In 2008, forteen years after the original MicroLogix 1000 was released, and three years after the MicroLogix 1100, Rockwell introduced the MicroLogix 1400.

This new micro PLC built on the success of the MicroLogix 1100, expanding on the built-in I/O count as well as the number of expansion modules supported.

Featuring 32 digital I/O, 6 optional analog I/O, and support for any seven 1762 expansion modules, the MicroLogix 1400 supported more total I/O than any previous model (up to 256 digital I/O points.)

As with the MicroLogix 1000, 1200, and 1100, the MicroLogix 1400’s DC input models supported either sinking or sourcing inputs. And like the MicroLogix 1200, the MicroLogix 1400 also came equipped with removable terminal blocks and wiring labels. If fact, the 1400 uses the same RTB’s as the MicroLogix 1200 40-point models.

As with the MicroLogix 1000, 1200, and 1100, the MicroLogix 1400’s DC input models supported either sinking or sourcing inputs. And like the MicroLogix 1200, the MicroLogix 1400 also came equipped with removable terminal blocks and wiring labels. If fact, the 1400 uses the same RTB’s as the MicroLogix 1200 40-point models.

The DC input models also supported six high speed inputs which all could be used as 100KHz high speed counters. The DC output models also included three high speed outputs which could be used for 100KHz PTOs, or 40KHz PWM outputs.

The MicroLogix 1400 was similar to the 1100 in the fact that it came with the same 8 pin Mini-Din serial port (COMM 0) that supported both RS-232  and RS-485. This port supported DF1 Full Duplex, DF1 Half Duplex Master or Slave, DF1 Radio Modem, ASCII, DH-485, Modbus RTU Master or Slave, as well as DNP3 Slave.

and RS-485. This port supported DF1 Full Duplex, DF1 Half Duplex Master or Slave, DF1 Radio Modem, ASCII, DH-485, Modbus RTU Master or Slave, as well as DNP3 Slave.

However, the 1400 also included a second serial port (COMM 2.) This additional port was a DB9 RS232C port that supported DF1, DH485, Modbus RTU, DNP3, and ASCII protocols.

The MicroLogix 1400 also came with an RJ45 10/100 Ethernet port as did the 1100. This port initially supported Ethernet/IP Peer to Peer messaging (not implicit I/O connections,) as well as Boot-P, DHCP, Web Server and Email functions.

The MicroLogix 1400 also came with an RJ45 10/100 Ethernet port as did the 1100. This port initially supported Ethernet/IP Peer to Peer messaging (not implicit I/O connections,) as well as Boot-P, DHCP, Web Server and Email functions.

In 2010, Rockwell released the series B model which enhanced the Ethernet port adding Modbus TCP and DNP3 over IP. It also added the ability to disable incoming connecting, duplicate IP detection, and unconnected messaging.

Being released three years after the 1100 allowed the 1400 to come with all the features of the 1100, as well as many enhancements. Beyond the expanded I/O, high speed DC I/O, and other features mentioned above, the MicroLogix 1400 also had the following improvements over the 1100:

More than double the memory (20K versus 8K)

More than double the memory (20K versus 8K)- Double the program execution speed (.7ms vs 1.5ms per 1K)

- Trigonometry instruction support

- Advanced math instructions (XY, CPT)

- Advanced timing instructions (Read High-speed Clock, Compute Time Diff)

- Backlit LCD

- IP Address settable from LCD

- Data Table accessible form LCD

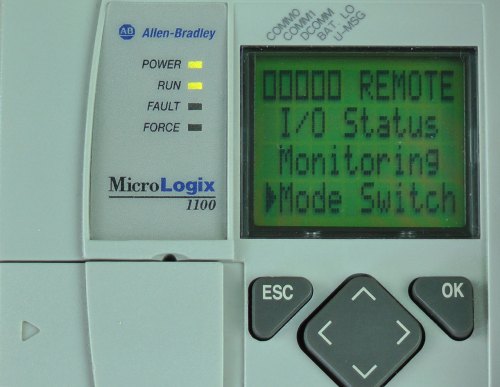

Just like the 1100, the 1400’s embedded LCD display replaced many of the standard LED indicators found on other MicroLogix models. It was used to display the status of I/O points, as well as change the controllers “mode.” It was also used enable the DCOMM setting for channel 0, and to display controller settings like the Ethernet address. It even supported displaying of user defined messages using an “LCD” instruction.

The MicroLogix 1400 was also like the 1100 in the fact that it included an additional 128K memory chip which could be used with the DLG instruction for datalogging. 64K of that same memory could also be used with an RCP recipe instruction.

The MicroLogix 1400 was also like the 1100 in the fact that it included an additional 128K memory chip which could be used with the DLG instruction for datalogging. 64K of that same memory could also be used with an RCP recipe instruction.

The MicroLogix 1400 was also programmed with the same Windows based RSLogix 500 software (version 8.1 or greater) that programmed the SLC-500 and other MicroLogix processors, as well as the MicroLogix only programming software, RSLogix Micro Starter ($129.)

Today, with it’s advanced features and many enhancements over the MicroLogix 1100, the MicroLogix 1400 is the pinnacle of Rockwell’s popular MicroLogix programmable controller family.

If you would like to find out more about the MicroLogix 1400 you can visit the manufacturer’s product webpage HERE.

Until next time, Peace ✌️

If you enjoy this episode please give it a Like, and consider Sharing as this is the best way for us to find new guests to come on the show.

Shawn M Tierney

Technology Enthusiast & Content Creator

Eliminate commercials and gain access to my weekly full length hands-on, news, and Q&A sessions by becoming a member at The Automation Blog or on YouTube. You'll also find all of my affordable PLC, HMI, and SCADA courses at TheAutomationSchool.com.

I'm a lifelong Technology Enthusiast who began programing in the early 80's on the Apple II and VIC-20 personal computers. After earning a degree in Electronics, I worked as a Certified Controls and Information Automation Specialist for 25 years before leaving to become a full time Industrial Automation instructor and mentor at TheAutomationSchool, as well as publishing industry interviews, news, and product how-to’s at TheAutomationBlog.com. If you're interested in my training, mentoring, or becoming a sponsor, please schedule a teams meeting with me via https://calendly.com/shawntierney/business-meeting

Latest posts by Shawn Tierney

(see all)

You must be logged in to post a comment.