Twenty Five things you need to know about using the PanelView Plus and View Studio

Part 5 of 5

Downloading runtime files to your PanelView Plus

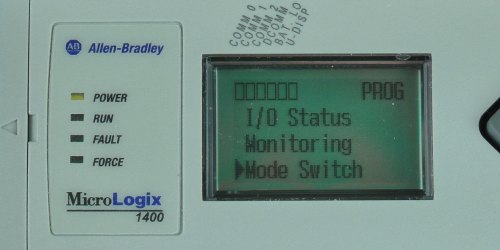

21) The PanelView Plus IP address is set via its configuration mode screen.

21) The PanelView Plus IP address is set via its configuration mode screen.

The PanelView Plus IP address is set via its configuration mode screen. By default, it’s set to DHCP.

You can use the “RSLinx Boot-P/DHCP server” utility to give it an address, but remember to change it “Static” or upon reboot it will request a new IP via DHCP.

22) Using an Ethernet cross over cable to upload/download is much faster than serial

Using an Ethernet cross over cable to upload/download is much faster than serial upload/downloads.

However, if your PanelView Plus is newer than your copy of ViewStudio, the Transfer Utility may not recognize the new PanelView Plus hardware. In these cases you may wish to transfer the file using a USB flash drive.

23) Manually add your PVPlus if it doesn’t show up in the Transfer Utility

If your PanelView Plus does not show up in Transfer Utility’s network browse, manually add it to the network driver you’re using inside of ViewStudio on the communications tab (found at bottom left of ViewStudio.) Then re-launch the Transfer Utility and you should see your PanelView Plus.

24) The PanelView Plus supports standard Compact Flash memory cards, and most USB Flash Drives.

The PanelView Plus supports standard Compact Flash memory cards, and most USB Flash Drives. The first time a user browses the CF card or USB Flash Drive from the file manager in the PVPlus configuration mode menu, it will create the correct path for runtime files if the path does not yet exist.

Note: Keep in mind Rockwell recommends always moving runtime files from the external CF card or USB Flash Drives to the internal memory before running.

Update: The PanelView Plus 6 now supports standard SD cards in place of CF cards, and also supports loading and running runtime files from these SD cards.

Backing up and archiving your ViewStudio Project

25) Use the Application Manager utility to backup and restore your projects.

When you are ready to make a back-up or archive of your project (or if you wish to rename or copy your project,) use the included “Application Manager” utility to zip your project up into an .APA (APplication Archive) file.

This is the best means to share projects with other developers, as the .MER (Machine Edition Runtime) files can not always be recovered into an editable project.

Update: With Version 6.1+ running on Windows 7 64 bit, older projects can not be opened until the database is exported on a 32bit OS.

NOTE: Links to all of the articles in this series are below

- Everything you need to know about the PanelView Plus, Part 1

- Everything you need to know about the PanelView Plus, Part 2

- Everything you need to know about the PanelView Plus, Part 3

- Everything you need to know about the PanelView Plus, Part 4

- Everything you need to know about the PanelView Plus, Part 5

Well that’s it for today’s article and the final five things you need to know before using a PanelView Plus. Please let us know what you think about this week’s series by leaving a reply at the bottom of this page.

And for more articles about the PanelView Plus, check out our PanelView Plus Blog Index.

Until next time, Peace ✌️

If you enjoy this episode please give it a Like, and consider Sharing as this is the best way for us to find new guests to come on the show.

Shawn M Tierney

Technology Enthusiast & Content Creator

Eliminate commercials and gain access to my weekly full length hands-on, news, and Q&A sessions by becoming a member at The Automation Blog or on YouTube. You'll also find all of my affordable PLC, HMI, and SCADA courses at TheAutomationSchool.com.

- First Look: Siemens S7-1200 G2 – Unbox, Wire, Program (S2E13) - April 17, 2025

- MaintainX: Prevent Unplanned Downtime (P236) - April 9, 2025

- First Time Using Ignition: Tags and Views (P235) - March 24, 2025

You must be logged in to post a comment.