Shawn Tierney meets up with Michael Bowne of PI to learn what IO-Link is, how it works, and when to use it in this episode of The Automation Podcast.

For any links related to this episode, check out the “Show Notes” located below the video.

Listen to The Automation Podcast from The Automation Blog:

Podcast: Play in new window | Download

The Automation Podcast, Episode 246 Show Notes:

To learn about our online and in-person training courses please visit TheAutomationSchool.com.

Read the transcript on The Automation Blog: (automatically generated)

Shawn Tierney (Host): Thank you for tuning back in to the automation podcast. My name is Shawn Tierney from Insights in Automation. And this week on the show, we have a special guest, somebody who hasn’t been on in four years. We have Michael Bone from PI. They’re the folks who manage technologies like PROFINET and IO Link.

And Michael’s come on this week to talk specifically about IO Link. We’re gonna talk about what it is. We’re gonna talk about when you should use it, and we’re gonna talk about the technical details of IO Link, like, all the things, like, engineering minds like to know about. So I think you guys are gonna enjoy this. It took about two to three hours to edit this one, and I really enjoyed going back through it.

You know, we recorded it, I think, four weeks ago. So I hadn’t seen it in four weeks, but I really did enjoy it. I really think you guys will enjoy it too. And that brings up another point. Organizations like PI and ISA and other organizations, they’re not vendors.

They don’t sell stuff. Right? And so this episode is not sponsored by a vendor. And, you know, as I was going through it yesterday, I was like, you know, there’s a lot of great slides in here. I wanna share it with the public.

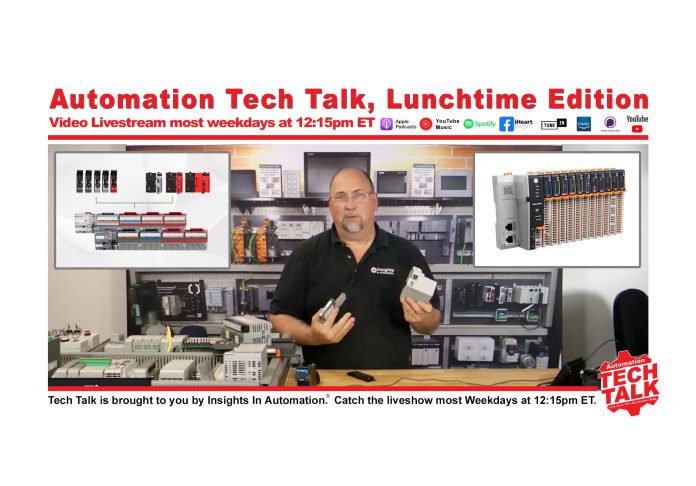

So I’ve decided to sponsor this episode myself, and I’ll use this as an opportunity to tell you a little bit about my company and the automation blog, the automation school, and the content I have planned to release this fall, including content on these products right here, all focused on IO Link. And I just actually did a live stream with these, products in front of me. I’ll be doing more tomorrow, and I’ll be adding lessons to my, courses as well on these products. So in any case, but before we get to that, let’s go ahead and jump right into the show and hear from Michael and learn all about IO Link. I wanna welcome back Michael to the show.

It has been four years. He was last on in podcast 76, back in September 2021. So just going on four years. Michael, thank you for coming back on the show. If you could, a lot of people may not remember four years ago.

Mhmm. So before we jump into your presentation, which which I am so excited about talking about IO Link again. But before we jump into that, could you please tell me a little bit about yourself and a little

Michael Bowne (PI): bit about PI? Yeah. Sure. First of all, my pleasure, to be back on on the podcast. It was a lot, a lot of fun.

I remember that back in in 2021, and, I’m glad to be be back doing it again. I started with PI North America in 2011 as the technical marketing director. And since 2016, I’ve been the executive director running the show and chairman of the board since last year. I, have the, let’s say, pleasure to serve as the deputy chairman of PI on a global scale since 2015, and I come from a prior to working for PI, I worked for a sensor manufacturer who had some interfaces on there that that brought me an introduct to to Profibus and Profinet. And before that, I studied, physics and and math at at Penn State University.

Just, really quick for those. I’m I’m sure many of you are familiar with with PI, but, it was started in the late eighties. Half a dozen companies and universities got together, and they wrote the PROFIBUS spec, and that evolved into the into into PROFIBUS DP and PROFIBUS PA for process automation in the early two thousands. PROFINET came under the umbrella. And the reason I bring all this up is because there are some newer technologies under our umbrella that I I think the audience might wanna know about.

Of course, EyeLink is is the one that we’ll talk about today, and that was in 02/2009. But there are some others like Umlocks, which is a location tracking standard. There’s one called MTP, module type package, NOAA, NAMR open architecture, also under our umbrella. And, basically, what we do is promote, maintain, write the specs, turn them into standards, and the work on those specs is done in working groups, which are staffed by volunteers, engineers from member companies. They donate their time to to develop the specs, for these technologies we have under our umbrella.

And we’re a little bit unique in that we’re decentralized. So we have competence centers and test labs and training centers located throughout the world. It’s not all just in one headquarter kind of place, and they’re all independent. But they have a contract or quality of services agreement with PI that says, hey. If you have a question about the technologies, go to a competent center.

If you want further training, go to a training center. If you want to to test the device, go to a test lab. And then they are all working with regional PI associations of which we PI North America is one of them. We were founded in 1994 by a guy by the name of Mike Bryant. At that time, we were called Probibus Trade Organization.

And we are the and now I didn’t come up with this this name. We are the North American Rio League. This is a an IO Link designation, a regional IO Link interest group, which means that we have a a separate contract and and quality of services agreement with the IO Link community to to promote and and work with members, specifically for IO Link here in in North America. And we’re nonprofit, member supported. I got nothing.

So you’re talking about products and and and stuff at the beginning. I got nothing to sell today. We’re we’re working solely on on technology.

Shawn Tierney (Host): You know, I do wanna throw out there, though, you have a great update every month about all the new products that fall in the buckets of IO Link, PROFINET, PROFIBUS, and a lot of those new products across our IO Link. So while they may not have products of their own, they do keep the, industry up to date on who’s joining up and signing up, for these new these you know, the jump on board and release new products that, that, you know, meet these specifications. And you know what? Maybe you’re not using PROFINET because you’re using brand x or y. You still probably use an IO Link.

So Oh, that’s for sure. Very interesting very interesting updates that you publish every month and, as a blog. And, I know when I was doing the news for a couple years, I would always, go to your site to look for new updates.

Michael Bowne (PI): Cool. Yeah. Yeah. I guess, I got a slide on that at the end, but the the you’re referring to the, the PROFINews.

Shawn Tierney (Host): Yes. The PROFINews. Yeah.

Michael Bowne (PI): Yeah. That’s a that’s that’s been a baby and a labor of love, for a while now. And and, oh, man, it’s it’s it’s incredible because every month, the most when we track this kind of stuff, obviously, the most popular article is the new products. Well, because that’s what, right, that’s what people want is the stuff they can buy, the stuff they can use. Yeah.

Yeah. That’s and we got another one coming out next week, and every month, we we push that out, and it’s always half a dozen or a dozen new products, half of which are are IO Link. I mean, it’s just growing like crazy.

Shawn Tierney (Host): Yeah. And you guys have had some good articles. I think you had a great series, and I’m now I’m stretching it. So stretching the old memory here. I thought you had a great series on on, MTP, which I really enjoyed.

Did did I remember that correctly?

Michael Bowne (PI): Yeah. We we try and, you know, we try and get some editorial content in there. It’s it calls it falls into, like, three main buckets. What’s new products? What are new trainings and events that are coming up?

And then and then some editorial content. I think I think what we’re driving at is I think we need to do maybe an MTP podcast here at some point in the down the road.

Shawn Tierney (Host): Probably. Yeah. Down the road. Definitely. Definitely.

I I’m still you know, I still have a very casual understanding of it. But, let me throw it back to you because I kinda jumped in and interrupted your your your, update.

Michael Bowne (PI): No. It’s good. It saves it saves us at the end when when that slide, we can just just jump over it. Now we’ve we’ve got it covered, and it’s and it’s an and it’s an important one. But you kinda you kinda gave me a nice lead into the to the next one, which talks about, the Ireland community.

And I’ll start from the bottom, work my way up as being fieldbus independent.

Shawn Tierney (Host): I just wanna break in here for a moment and thank you folks in the audience who’ve signed up for my membership program. Really, really appreciate you all. Eighteen months ago, after reviewing ten plus years of being on YouTube, you know, it was pretty obvious that there’s no real revenue on YouTube. I mean, it comes in at maybe 1% of my monthly expenses. And so that ad revenue there is just not something to rely on going forward because it’s not something that’s been reliable in the past.

And so I set up the membership program both on YouTube and at the automationblog.com. And I wanna thank all of you who signed up. I, we have a $5 tier, which I know most people sign up at, and then we have a couple other higher tiers. And so I just wanted to thank you all for doing that. You are actually the membership program’s probably 3% of my monthly, revenue.

And so that’s, you know, one or two times more, than, what the YouTube revenue was. So thank you all for that. And I hope that, some of you who are not part of the membership program will consider becoming a member, supporting my work so I can do videos that are not always sponsored videos. Now I love sponsored videos. I love it when a vendor sends me a piece of hardware and then sits down with me and teach me how to use it so I can create a video ad free and share with you on how to use that product, or maybe they just come on the podcast and sponsor it to make it ad free so we can tell their story about their product or service.

And I I will continue to do that going forward, but I would really also like to do more audience generated type of, content. So content where you generate the idea and say, Shawn, why don’t you try this? Or, Shawn, why don’t you do this? And a lot of those topics that the audience wants to see, they’re not necessarily topics that the vendor wants to promote with advertising dollars. Okay?

And so that’s the whole purpose of the, membership program. Like I said, right now, it’s around 3% of my monthly income comes from and I’m talking about the business income, not my personal income, the business income. 3% of what the business needs to, to move forward and pay its bills every month. But, still, I that that, you know, so many of you have decided to jump in and support me. I just wanted to stop and say thank you very much from the bottom of my heart.

And if you’re not part of the membership program and you’re doing financially well, please consider if you enjoy. This is episode two forty six of the automation podcast. Every episode has been free. The audio has been free for all 246 of them. And most of those episodes I funded myself just by well, you can understand how you fund something when you don’t have the income coming in.

But in any case, if you enjoy it, please consider becoming a member, and we can branch out and do other things together. And with that, let’s go ahead and jump back into this week’s episode and learn more about IO Link.

Michael Bowne (PI): So like you said, yeah. I mean, organizationally, the IO Link community came to PI in 2009 and organizationally under PI because we have the infrastructure for working groups and and IP policies and contracts and things like that. But the IO Link community has their own steering committee, and from the from the outset and from every IO Link event that we do and everything that we do is is independent of, of any Profibus or Profinet stuff. And we try really, really hard to maintain that independence, no matter what vendor you’re using. And there, at this point, we’ve got 500 companies in the IO Link community, and it’s really just growing by by leaps and bounds.

So we kinda track this stuff by nodes and all the IO Link companies. They send their node count to an independent auditor, collects the counts, and gives us back an an an anonymous total. So we don’t know where or who is selling them, but we get the total. And you can just see this this hockey stick exponential growth. Particularly in 2023, there was some supply chain over purchasing that that went on.

I mean, that’s like we’re looking at a a growth rate of 89% there, which is obviously unsustainable. But still, last year, 9,700,000 nodes were added. Again, because it’s field bus independent, it really has no competitor. And that’s what’s kinda cool about IO Link. I mean, you wanna do and and you don’t need to choose a field bus and therefore get IO Link.

You can use any field bus or industrial container protocol, and IO Link works with it.

Shawn Tierney (Host): You know, I wanna just, mention for the audio listeners. If we go back to 2012, it looks like we’re probably at the 1,000,000 mark or below it. And as you go to, you know, 2022, you look like you’re 35,700,000. Is that 2022 or 2023?

Michael Bowne (PI): Yeah. That’s the 2022. Exactly. 35,700,000.0. Yeah.

Shawn Tierney (Host): And then at, the end of twenty twenty three, we’re at 51.6. So you talked about that, you know, overbuying. And then at the end of 2024, we’re at 61,300,000.0. So you can just see from, you know, 2022 to, 2024, you went from 35 to 61. So the adoption, like you said, it’s a hockey stick.

The adoption has really picked up. And I think you you hit the nail on the head because it is fieldbus independent. It’s a way to just get more information out of our devices, like sensors and photo eyes, you know, and it’s just you know? I mean, though, these chipsets that come in these, devices now are just amazing.

Michael Bowne (PI): And that’s what, I mean, that’s what the whole point of this is. You’re you’re not gonna put a $5 ethernet chip, like, enter $5 ethernet interface on a $15 proximity sensor. But computing and memory has gotten really, really small and really, really cheap that it’s on just about everything. And so this proximity sensor not only can tell you if, like, for example, let’s say it’s on a conveyor belt. It cannot only tell you if the box is there or not, but it can tell you how many blue boxes would buy or how many red boxes would buy or if the box that’s going by is off kilter or or misaligned or something like that.

But how do you get that data out in in inexpensively, and here we are. IO Link is is the way to do it.

Shawn Tierney (Host): I’m sad to see a lot of these sensors too come with humidity, temperature, and all these other things should be like, really? I can get that out of my

Michael Bowne (PI): photo eye. But yeah. Multivariable. Exactly. Yeah.

Yeah. You know, traditionally, with an analog interface, how did you get that? You couldn’t get it. Mhmm. But now with a digital interface, which is what we’re talking about, digitalization in the last meter, now you can get that informate that data, that information, and do some pretty cool stuff with it.

Shawn Tierney (Host): Yes. You can. Yeah. I’ll talk

Michael Bowne (PI): a little bit about the architecture a little bit here to kind of get a little bit into the technical side of things about how IO Link works, but it they’re kind of some main devices, and that’s the IO Link masters and the IO Link devices. And these IO Link masters are available for we have here 16 different industrial Ethernet or field bus systems. 21 manufacturers offer central PLC, like an IO Link master built into the backplane of the PLC if you so desired. And the number of devices that so that hockey stick we showed before is just exploding. I mean, we’ve got 60 something million sold, and we have tens of thousands of unique IO Link devices from hundreds of different device manufacturers that have implemented this interface.

And for those that if there’s anybody on the podcast that wants to do this and add this to their sensors, there are a number of different companies that help with, product design, either with the chips, the transceivers, the software stacks, and then a number of companies that help provide technical support in order to do that. So an IO Link system kind of is made up of four parts. Like I said, you have the IO Link master. That’s the gateway between the IO Link devices, the IO Link interface, and the higher level communication system, such as the fieldbus or the in industrial Ethernet protocol or backplane. You have the devices.

This is the exciting part. Your sensors, your switch gears, your valves, your signal lamps, maybe some simple actuators, whatever the case may be. You’ve got a IO Link cable, just a three wire unshielded, super simple connection between the master and the devices. And then every device has an IODD or IO Link device description file, and I’ll explain how that gets used to engineer and parameterize the IO Link system and the and the devices. And what this kind of enables you know, traditionally, communication only reached the IO level.

You had connection between the PLCs and the and the the the IO, and then it kinda stopped there because all those sensors and actuators were not accessible. They were analog, and you got your one process data. You brought process signal, and that’s where it ended. But with IO Link, what we do is we enable that communication bidirectional, cyclic and acyclic, and that’s the cool part, all the way from higher level systems, not only to the PLC or especially from the PLC, but down all the way down to the simple sensors and actuators, which are now accessible. And you kinda touched on this before where these chipsets have gotten really, really smart and really, really powerful.

And it’s not that the it’s not that any of these use cases that are that are being solved with IO Link that none of them are new. What’s new is the ease with which they can be solved. So because you can get all this extra data out, things like OEE, showing things like downtime tracking, track and trace, predictive maintenance, for example, remote monitoring, recipe management, SPC, all these things. It’s not that these use cases are now being solved. The you know, we’ve we’ve been doing this for a long, long time.

It’s just the ease with which because because it’s a standard and because all this stuff is standardized in how it gets from the the the device to the master and upwards to the controller, it just makes it easier. If you spend all your effort trying to gather and collect and sanitize the data because every device is different and, you know, that’s just that’s just a mess, and the ROI disappears really fast on any kind of project to do that. But if we have a standard on how to do that, then we make it very, very easy to do, and everything can come in, quite nicely. And and and it just and it just works a whole lot easier. You start getting access to that data.

And so what we’re starting to see is connections being made. You know, you talk about the the flattening of the traditional automation hierarchy where now not only is that IO block or that sensor connected to a to a PLC, but it’s got some extra data. Like you said, like, this little photo I might have a a a temperature or a a moisture, you know, sensor also in there, just because it’s part of the the chipset. But the PLC don’t care about that. He just wants to know about the, you know, the information from the photo eye.

So what do you do with all this extra beautiful information that isn’t necessarily processed data? Well, maybe the MES wants to know about that. So how do you get that? And in a running factory, in a brownfield environment, rule number one is don’t touch the running PLC.

Shawn Tierney (Host): Yeah.

Michael Bowne (PI): And rule number two is see rule number one. That thing is running, and any minute of downtime costs more than any one thing on the on the factory floor.

Shawn Tierney (Host): Before we go on, I did wanna break in here and tell you a little bit about my website, theautomationschool.com, where I do my online training. I also do in person training. And you probably don’t know that that all started back in 2014 with a Kickstarter I ran for my first PLC basics course. At the time, it was called microprogrammable controller basics, and I ended up changing it just the PLC basics. But in any case, since then, I’ve had added a dozen courses on a various number of topics, and you’ll find them all at the automationschool.com.

But what I really wanted to talk to you about is why. Why did I do that? Well, I had spent twenty five years as a certified authorized Rockwell Automation distributor specialist covering PLCs, HMIs, SCADA, MES, and other stuff too. Right? And I knew from visiting, customers in the plant every single workday, almost every workday, that there was a real need for affordable training.

So the first thing is, you know, large companies have large expensive, large paychecks, and lots of overhead, so they gotta charge a lot. Right? And so that was a problem because a lot of the people I was working with, you know, the controls engineers, automation engineers, high end electricians and technicians, they had to fund their training themselves. Their company was sort of like, no. We trained this guy back in the nineties, and then he will have to get a better job.

So we’re not spending money on training. And so all these people were having to train themselves, and it was unaffordable to either, you know, buy the the, vendors courses. Or even if the the company did have training dollars, it was unaffordable to send them away for a week to a $3,000 course somewhere halfway across the country, probably $3,000 worth of travel and hotels too. Right? And then they go where without one of their smartest guys, right, one of their best people, because you you that’s usually who you’re gonna train and and uplift through the through the organization.

Either people are doing good on the lower level, you wanna bring them up and train them on automation. And so that’s why I started the the, automationschool.com because of the the try to provide I knew the the courses would never be Hollywood quality. I mean, this isn’t Hollywood quality. Right? But I knew it could be helpful and and, you know, be affordable by just filming them in my garage.

Right? And, you know, picking up some used equipment and putting together the episodes. And the site has grown so much. We have thousands of, students from over a 150 countries. We have hundreds of, vendors we work with.

But the other thing I did is, is made up by one’s own forever. Right? So more like an ebook or an audiobook or an m p three album. Right? And the reason I did that and I understand why the vendors don’t do that because they’re like, well, they’ll sign up one guy in the I and e shop, and he’ll share his password for everybody.

You know, that could happen. Right? People could rob a bank too. But I’m like, you know, most people, when they buy a course and I saw this. I was on an independent platform for a while, and on that platform, they showed you how the progress of every student.

Most people buy the course well before they’re ready to take it. And I’m like, I’m not gonna charge people a monthly fee or only give them access to to a short window if, you know, they have good intentions now, but it takes them a while to actually free up their schedule to get into the course and take it. So that’s why my courses are buy one’s own forever. And it can you know, as they grow, the price goes up because I’m adding more and more content, and I do split them out and make cheaper versions over time. But, those people who buy in early, they get the like, my s seven course.

Like, I think it originally came out at 40 or $50, and now it’s $200 because I’ve added so much to it over the years. But in any case, same with ControlLogix and CompactLogix. And then the other thing too is I want them to be able to take it more than once. Right? So if you take a let’s say you take a ControlLogix course.

Right? You don’t use it for a couple years, you probably gonna have to take it again. And I don’t want you to feel like you have to pay a monthly fee to do that. It’s like an ebook or an m p three album. You bought it.

You bought access to it, I guess I should say, and now it’s yours. Right? And the other thing too is I support my students personally. Okay? So I check the website every day for questions, every work day.

I should say, you know, I do take Sundays off. So in any case, if you’re if it’s a work day, though, and I’m working, I’m not on vacation or traveling for business, I’m up there. I’m answering questions. And I should say, even when I’m traveling on business, I’m I’m on there answering questions. So although if I don’t have any hardware, there’s some questions you can’t ask.

Right? I guess I should have said some questions you can’t answer. But in any case, I just wanted to share that with you. Theautomationschool.com, a high quality online courses, five star rated, buy once, own forever, and guess what? I’m updating all the PLC courses, and if you already own or buy one of the existing PLC courses, you not only get the updated lessons that get added to that course, you get the new course completely free.

So I’m not gonna charge you for just an updated version of a class on the same core on the same product. Right? That would be kinda silly in my opinion. So, I hope you guys appreciate that. Again, if you didn’t know any of this, if you have any questions, if you go over to the automationschool.com, at the very top of the site, you’ll see links to contact me, set up a meeting, leave me a voice mail, fill out a form.

You know, I have many ways you can get in touch with me. And if you have multiple people you wanna sign up, I do have multiple seat discounts starting at three seats. And, I do actually work with a number of Fortune 500 companies who, you know, enroll maybe 10 people at a time to get that discount. And you know what? Unlike the big vendors, if somebody you sign somebody up and they all take the courses, I’ll let you replace that person for free of charge.

You don’t have to pay anything extra. If you sign up Joe and he decides to quit or leave or not to learn, you can put Bob in his place. That’s not a problem. Now I have said some situations where the same spot kept getting replaced or replaced or replaced. At some point, I do charge a maintenance fee to to switch the names out.

And then, hey. Look. If Joe leaves and he took, you know, two out of three courses, I’ll prorate refilling that seat with the new person. Right? So whatever percentage of the lessons he took versus the total number of lessons, I’ll prorate it.

So, you know, we’ve had number of cases where somebody goes through half of the content then leaves, so we can reset that seat for half price. And I that’s something you won’t find, any major vendors doing as well. So if you have any questions about that, reach out to me over at the automation school dot com. And with that said, let’s jump right back into this week’s episode of the automation podcast.

Michael Bowne (PI): In a brownfield installation, what we’re seeing these these cool little edge gateways, And what they’ll do is they’ll grab the bus, they’ll collect some data, and pump it out the other side via, you know, maybe an IT protocol that that the IT guys wanna know about or, you know, like an MQTT or an OPC UA. Of course, in a in a greenfield, in a new installation where you’ve got a brand new PLC, yeah, get the data there. That guy has all the brains, has all the all the information in one ply in all in one place, so get it from the PLC. But in Brownfield, I the edge gateways, even some IO Link masters are being put on the market that have not only an industrial Ethernet interface, you know, just on one port, on the same port, industrial Ethernet interface for control, but that interface will also speak like a higher level IT protocol like an MQTT or an OPC UA, so you can get it even from the IO Link master that data is is accessible. So the different ways to get it, and, and that’s kind of the whole point is is getting that data from the sensors to the to the master and then further upwards.

Shawn Tierney (Host): We actually covered a product on the show that had two ports. It had one for your fieldbus

Michael Bowne (PI): Yeah. And then it

Shawn Tierney (Host): had a separate one for your IT or your IOT or your MQTT, which I thought was so inventive too because now the control system gets its data, and it’s under control. But reporting wise, you know, that’s kind of the best of both both worlds. You don’t have to have two sensors. You can send it to data both ways. And, yeah, just it’s the way you can do with these things and, you know, a lot of the sensors you probably have out there, I’ve noticed that some vendors, every sensor they sell is IO Link.

So Yeah. You may already have it installed and not know it because the price difference to add it to some products. Once you get up to the fanciest sensors, of course, not the simplest sensors, but once you get up to the fanciest sensors, it’s it’s, you know, there’s a lot of horsepower in that chipset. So, you know, they can add IO Link for for pennies on the dollar. So very interesting stuff, though.

Michael Bowne (PI): Yeah. That’s that’s a good point. And and, you know, of course, we could spend all day talking about IT, OT, and the segmentation of networks and all who’s who owns the IP addresses. And we I mean, that’s a whole separate topic. But in cases like that, yeah, it’s cool.

You got a separate port. IT can do what they want on their one port. And if but, hey, don’t touch me in the control realm because Mhmm. This is my this is my realm. And and you bring up another good point, and that’s kind of there’s a I don’t I don’t wanna say that, you know, there’s there isn’t, like, a thick black line between, okay, this sensor is simple, therefore, should have IO link, or this sensor is complex, therefore, should have its own industrial Ethernet, interface.

There’s almost a little bit of a gray area, but you’re right. I mean Mhmm. We kinda leave it up to the vendors to decide. Hey. My thing needs the horsepower that and it’s so complex that I need something like, like, an industrial Ethernet protocol.

But, oh, you know what? This other central line is tailored for low cost, and so, therefore, I’m gonna put IO Link on it. But that’s, you know, that’s up to them to to decide. So when we talk about IO Link in terms of benefits, we kinda like to make the analogy with USB because everybody knows USB. You got your USB cable.

You plug it into your computer on one end. On the other end, you plug it into your you know, you plug your mouse in or you plug your keyboard in, and you plug your key your printer in. Automatically, it it uses the same cable. It’s always the same. Everything everybody’s using that interface, and we kinda see the same thing with IO Link where it’s just a unified, unshielded three wire sensor cable, and it can use be used with all IO Link devices.

Up until now, you know, if you had smart devices, right, memory and computing power is smaller and cheaper. Up until now, to get that extra information out, you would need multiple cables. The wiring is time consuming. It’s expensive. They’re large, costly to to install and maintain.

But But with iolink, you just you just plug it in. It’s a simple m 12 plug, and then you don’t have all these spare parts of different cable types. It’s just one cable and, easy to maintain, thin, flexible. I’ve got a I’ve got an example here I’d like to highlight, and I’ll try and talk through it for those that are that are listening instead of instead of viewing. This is an example of 256 IOs via 16 fieldbus modules.

So, like, fieldbus like remote IOs or whatever the case may be. So we’re connecting them to a PLC out in the field. And to do that, we would need 16 fieldbus modules in order to do that. These are just let’s let’s call them simple DI, you know, digital input proximity sensors. Mhmm.

Shawn Tierney (Host): Mhmm.

Michael Bowne (PI): With IO Link, we can do that via just one fieldbus module. So that’s just one IP address or one IO Link master. So already you’re cutting out 15 of those more expensive devices. And then we use what are called so called IO Link hubs, which bring those DI signals, put it all on one IO Link connection, put it into IO Link master, and send it out the other side. And with that, we can connect if you imagine these 272 IOs as shown here via just one fieldbus module.

So it’s showing just huge, huge, huge savings simply on cost alone, due to the wiring. And, that that one cable, it fits all sensor types. So simple sensors, like a proximity sensor all the way up to complex devices like pressure, temperature, signal lamps, and even simple actuators all use the same IO Link cable.

Shawn Tierney (Host): So where an IO Link device would be giving you not just on or off, but a lot of other information and some of that analog information. If all you had was a dumb device, well, now I can put 16 of them or so, you know, some number of them together Mhmm. Bring them into a hub. And each since each device only has an on or off, where a regular IO Link device would have lots of other information, you can now just join them all together and say, okay. Here we go.

Here’s inputs one through x.

Michael Bowne (PI): It’s, almost like multiplexing, put it all together on one and then Mhmm. Pump it out the other side. Yeah.

Shawn Tierney (Host): Perfect.

Michael Bowne (PI): The other way we relate IO Link to USB is kind of in the the identification and parameterization. So if we look at how you plug your printer into your computer, you plug it in, and automatically, your computer says, oh, okay. I know that that’s a HP something something desk check printer and and okay. How do you wanna do you wanna do color or black and white? Do you wanna do full duplex?

Do you wanna do back and white, back and front on on the printing? And the same is true for for IO Link. So you plug in that IO Link sensor into your IO Link master. It reads it. It says, hey.

The dialing says, hey. This is who I am. This is my type. This is my serial number. Every device has a vendor ID and a device ID.

And then the IO Link master goes up and gets the IODD file, and I’ll show that here in a little bit, and then you can start that parametrization. And it’s just like it’s just like a USB. It’s it’s, no special knowledge is required. You can format changes very, very easily. You can even do them on the fly, for example, with an HMI on the on the machine.

And, the identification methods make sure that you don’t plug in a wrong device into an IO Nialink port, which could stop the machine. It’ll it’ll it’ll recognize that and prevent, incorrect connections. It allows you to exchange devices very easily of the same type or the the same same manufacturer, same same device. So just like USB, it it it kinda works in that way. And then the other way, it’s kind of like USBs in the diagnostics, and this is a really, really powerful part of IO Link.

So when your printer says, I’m out of paper or I’m out of toner or there’s a paper jam, it sends that signal, standardized signal to the to the computer, to your computer, your PC, and you know exactly what what to do, how to fix your your printer, why your printer isn’t working the same as true for IO Link. We’ve standardized these diagnostics. So this is a, a photo eye saying, hey, under voltage or over temperature or the the window on the photo eye has gotten dirty, so signal quality is deteriorating. So we standardized all this, so that these diagnostics all come in the same way, and, you can, you know, fix any any problem as fast as possible to to to, minimize downtime. And in the case of things like signal quality, hey.

The the the window’s getting dirty. This enables things like preventative maintenance. Oh, I know I’m going into a planned shutdown next week. Now’s the time to go out and clean those sensors kind of thing, because I know that they’re I know that the signal’s going is deteriorating. So some cool things like that, that wouldn’t be possible with a traditional analog signal, which we’re showing here.

And it also makes really no sense. I mean, in this example, what we’re showing here is a generic this is a pre pressure sensor. You know, it does its measurement. It then does some amplification, and then to stabilize the signal, it does an a to d, puts it into a micro, which does some temperature compensation linearization. But then, traditionally, prior to IO Link, what you do is then do another data a to send it out via zero to 10 volts or four to 20 milliamps, whatever, into the into a, an a to d card on the backplane of the PLC, I mean, this is just this is just crazy.

It’s it’s time consuming. It’s, the the signal is still susceptible to interference. The the analog inputs on the cards on the PLC are expensive. There’s manual calibration of the signal. But with IO Link, it just makes sense.

You take that signal right from the micro, pump it out digitally via an IO Link inexpensive interface to your, to your IO. And, we use that unshielded three wire inexpensive cable,

Shawn Tierney (Host): and

Michael Bowne (PI): then you get all those parameters and diagnostics. And, really, that’s the point of using IO Link is all that extra data, all that extra information that that comes along with the the process data.

Shawn Tierney (Host): Yeah. And so those of you who are listening, I mean, what we saw there was to to shoot out a four to 20 milliamp signal or zero to 10 volt signal, it had to convert it from the digital value that was inside the device to analog, then I have to pump it out. And, you know, we always have to worry about noise and, you know, shielding and all that, you know, depending on the length of the run. And then in the PLC analog card, it’s converting it from analog back to digital, so you have that zero to 32,000 value or zero to 64,000, whatever your PLC does. And so IO Link does eliminate that.

It eliminates the noise of your traditional analog. And I know I’ve met so many customers say we have no noise issues on our analog, and that’s great. But not everybody’s in that same boat. So you’re eliminating that d to a and then a to d, and that’s that’s you’re keeping everything digital. So you’re not only getting a cleaner, more accurate value from your device, you’re also getting all those additional pieces of information and the ability to be maybe configured to products.

Some of these products need to be changed based on the type of product they’re sensing, you know, the type of fluid going through, the recipe that’s being drawn, the lighting, the colors. So all those different things, you you know, with a typical analog signal, you’re not gonna be able to send back and do a configuration to it. So, go ahead. Back to you, Michael.

Michael Bowne (PI): No. You’re right. Exactly. We we have I I took this line out of this deck for the for, you know, for for brevity, but we show examples of of particularly food and bev, right, where you have batches, different I’m running a different batch. I’m running a different product.

I need a different label on the on the bottle or whatever I’m running through the the the machine. You reconfigure that via the HMI. It sends all that stuff down to the sensors. Okay. Now I know I’m looking for I should be sensing this instead of this.

Shawn Tierney (Host): Yeah. It could be a clear bottle sensor, the clear bottle detector that the bottles change colors. So it’s has a different setting, or it could be background suppression depending on the color of the product. You need a different setting or a color sensor. Maybe you’re making different products and the different colors, and so, you know, all this is now configurable through your PLC, through your control system, through your HMI, which I just think is so cool.

Michael Bowne (PI): Yeah. It’s it’s it’s super cool. Alright. Let’s get a little bit technical here. I think for some of the engineers, that might be nice.

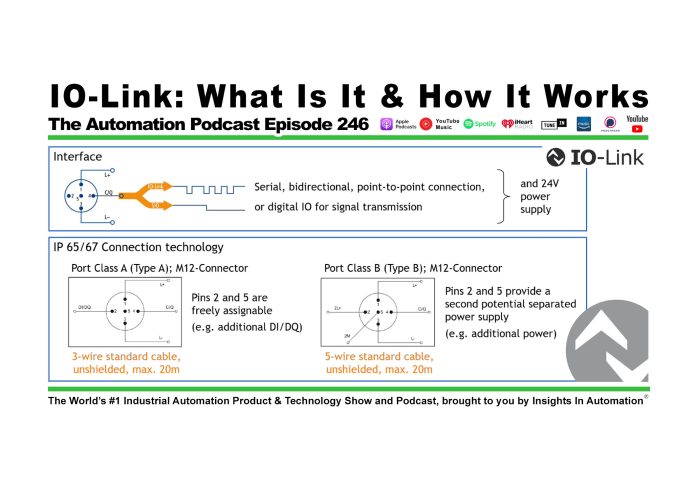

The IO Link signal and 24 volt power supply, like like we talked about before, it’s it’s an m 12 connector. So you’ve got five pins. Your pin one is your high, pin three is your low, and then pin four is your CQ line. That’s that’s where the IO Link digital signal lives. It’s serial.

It’s bidirectional. It’s point to point. And then we also have on that same pin four, if you so desired, you could also parameterize your device via IO Link, set it all up, and then put it in what’s known as a CO mode or simple IO mode. And I’ll show that on the next slide too if maybe you’ve just got a digital IO, that you want a fast switching interface. So pins one and three are our power.

Pins two and five are freely assignable. So for example, if you wanted to use that pin four for your IO Link signal and then separately have your own DI or DQ line, you could do that using a three wire, four wire, five wire cable. And then what’s cool also in IO Link and we’re starting to see this more and more is we call this port class b, same m 12 connector, same five pins, but pins two and five provide a separate power supply for additional power because and this is cool. We’re starting to see more and more IO link just, like, simple actuators Mhmm. On the market.

And that’s really neat. So let’s say you’ve got some simple linear actuator, not not a complex, you know, driver, you know, or motor or something like that, but a a simple linear actuator. You can drive that via IO Link if you just gotta move something really, you know, maybe maybe even within connected to the same ports, on the master as some other sensors, and so you can do that logic in the master itself, you know, simple simple stuff like that. But that’s also possible with IO Link where you can drive it, not just sense it, but also actuate it with with IO Link. So that’s that’s some cool stuff that’s coming down the line.

Shawn Tierney (Host): You know, and I found that all the IO Link devices I had here, they came with the SIO mode already set up. So I was able to use the photo eyes and the proxies and all the other devices just as simple IO devices and without even touching the IO Link side of it, which I think is cool because, you know, in in many cases, you just need a photo eye to get up and running. Right?

Michael Bowne (PI): Yeah. And that’s and that’s how they come out of the box. So out of the box, it’s in that CO mode. And I think you you kinda touched on this before. Maybe many customers have IO Link devices Yeah.

On their machine. They don’t even know it Mhmm.

Shawn Tierney (Host): Because they

Michael Bowne (PI): took it out of the box. They needed that photo. They plugged it in and away they went. But there’s also that all all that extra stuff. If they wanted to, they could get down into the IO Link part of it.

Mhmm. Maybe to reparameterize it, or what if you got to change, you still wanna use the CO mode. You just want that digital input. What if you wanna change the switching distance, for example, something like that? I don’t want it to switch at one meter.

I want it to switch at two meters or whatever. So all that all that can be configured via IO Link. So on the if we if we talk about the the IO Link communication itself, there are three transmission speeds, comms one, two, and three. Comm one is 4.8 kilobits per second. COM two is 38.4 kilobits per second, and COM three is 230.4 kilobits per second.

IO Link masters support all three comm modes, but devices are free to choose based on what they’re sending. If it’s temperature, maybe you don’t need COM three because that’s changing more slowly than something like like like we’re talking about a proximity sensor, which may want to send that a little bit more quickly and uses that that COM three mode. Many, many devices use COM three mode because still two hundred two hundred thirty kilobits per second, that’s, you know, that’s not gonna that’s not gonna kill you. And then a typical cycle time, because this is the question we get all the time, is what kind of cycle time can be achieved? It’s about a millisecond at at com three.

So if you’re, you know, trying to go submillisecond, you know, maybe IO Link is not is not the solution at that point. But for many, many applications, that one millisecond cycle time can can, can accomplish whatever they need to. And then what’s cool is that from the EyeLink master’s perspective, it’ll have eight or 16 sensors connected to it. Each device can be set independently. So on this port this device, I’m talking at this comm rate and this cycle time.

This other port number two, I’m speaking at a different transmission speed and a different cycle time and so on and so forth, you know, so that you’re not sending data unnecessarily that is simply just being sent for the purposes of being sent. And that’s and that’s pretty cool.

Shawn Tierney (Host): And a lot of times, you don’t because you’re not reading a digital on off, you don’t the speed, you’re you’re actually getting a value, and that value a lot of times your PLC is not gonna be running faster than a millisecond scan time. So if you’re getting your value updated, you know, faster than the PLC, then that’s a then then that’s really what you need. Do you know how fast is your PLC running? How fast can your program controller use that value? And, you know, I’d be hard pressed to see a lot of applications where they’re breaking that one millisecond update rate.

The other thing too is just because we’re talking at the speed doesn’t mean the actual calculation is even possible in a millisecond. So, you know, temperature changes, things that that sensors there’s limit limitations to the physical world. You know? And, you know, I I don’t know if anybody’s ever said this to you before, Michael, but when I first saw the whole comm thing, I thought that was confusing because having grown up with PCs, I always thought of comp one, comp two, comp one group. Right?

And these are really just bought what I would call from the old days, sewer rates. Right?

Michael Bowne (PI): Yeah. Exactly.

Shawn Tierney (Host): Exactly. Insight why why they is it just maybe because it was the standard started overseas or any idea why they went with CALM?

Michael Bowne (PI): I’m not gonna lie to you. That’s the first time I’ve gotten that question.

Shawn Tierney (Host): Really? Okay.

Michael Bowne (PI): Why they’re called that yeah. Let’s just let’s just rewrite this. They call it BOD one, BOD two, BOD three.

Shawn Tierney (Host): I know. It’s just so weird. But, anyways, sorry sorry, audience. I just have

Michael Bowne (PI): That’s a good one. That’s a good one. Nope. I’ll take that one back. Alright.

So IO Link data comes in a couple different flavors. You have your process data. That’s your bread and butter, what you’re using to run the run the factory. Transmitted cyclically in a Telegram, the the data size is defined by the device, and it can be up to 32 bytes for each device, both input and output. Along with that comes a value bit indicating whether the process data is valid or invalid, and this can be transmitted is transmitted cyclically with the the process data.

And then you have things that happen acyclically. These would be device data like parameters, identification data, diagnostic information, and these happen on request of the IO Link master. Obviously, a lot of that happens during startup, but also can happen during runtime if, as shown here on the slide with the with the last case, events can be error messages. So the the, the device will set a flag. Hey.

There’s a short circuit or so, and then the the master can pull that device for more information, more diagnostic information, based on that event flag that’s that’s set by the set by the device. And so, the the question we always get at this point is, how do I make this all work? How do I integrate this stuff into my into my plant?

Shawn Tierney (Host): Before we go any further, I did wanna jump back and tell you about a service I’m doing that I don’t think I’ve talked about very much, and it’s comes in two different flavors. First of all, I’ve actually had some vendors and companies reach out to me and say, Shawn, I know you don’t wanna travel all around the country with all your equipment. Right? That’s not what you do, but we want you to come out and teach us something. Would you come out and do a lecture?

We’ll set up our own equipment. And, can you come out and just run us through some of the products and teach us some of your knowledge, and you don’t have to worry about bringing all the equipment with you. And so that’s something I really don’t talk about much, but I do wanna tell you that if you’re looking for training and you need it on-site, of course, you do have to pay for my travel time. But if you do want me to come out for a day or two days or for a week and do training on any of the products I train online now. Now if you want me to come out and do training on a product I don’t already have a curriculum on, I can’t do it.

The building the curriculum is where all of my costs is on the training. Right? I shouldn’t say that. The web service in in in the back end does cost something every month as well, but most of the time it goes into and that’s really what being self employed is it’s time. Right?

Most of the time goes into build building the curriculum. So if you have a need for somebody like Shawn, we can’t do a webinar. We can’t do a Teams meeting. We we can’t do online training. We want you to come out.

And, again, I just got a call on this yesterday. Yes. I can do that. As long as the curriculum I’m gonna teach you is something I already have existing. And, I’m not gonna hand out lab books.

We can buy you lab books if you want. People sell great lab books for $80.90 dollars a pop. If you want lab books, I’d be more than happy to include that in the quote. But in any case, I that’s one thing I do. The other thing I’ve been doing with vendors is they’ve hired me to come out and interview them at their trade show.

So, usually, what happens is somebody will sponsor a podcast for $5.99. They’ll come on. We’ll do the interview. I’ll edit it all up. I’ll put their links in.

We’ll talk about the thumbnail, and then we’ll release it ad free. Right? And so that covers my cost of producing that episode roughly. Right? We just raised it from $4.99 to $5.99 because most of the shows were were actually upside down on, so we need to raise it a little bit to make sure we’re covering our cost.

But in any case, sometimes vendors have, you know, they have their own trade show, and they may have all of their product specialists there. And they’re like, hey, Shawn. We would like to do six or seven interviews at the trade show. Would you come out and actually record them there? We’ll pay your flight.

We’ll pay your hotel and your expenses to get there and back. And so that’s another thing I haven’t talked about much that I’m doing. I’m working with some, you know, top five vendors to do that, and I’ve done it in the past. And so I did wanna explain it to you if you’re a vendor listening or if you are, talking to your vendor, like, you should have Shawn come out and interview all your people. You have them all in one place.

Let them know that they can contact me about doing that. Again, you can contact me at theautomationblog.com, LinkedIn, YouTube, theautomationschool.com, pretty much any way you want. You can write me snail mail if you want. But in any case, I do wanna share that, and we also have in person training. I think I’ve talked to you guys about this quite a bit.

We do custom in person training for as little as two people, $900 a day up to four people. And so if you wanna get some people in here, we can actually do Allen Bradley and Siemens in two days back to back. One day Allen Bradley, one day Siemens. So if you wanna learn two PLCs in two days back to back now I do have somebody ask me, hey, Shawn. Where’s your schedule of upcoming courses?

And back in my previous life of twenty five years, we were always trying to sign people up and then canceling, you know, events and classes because, we wouldn’t get enough people to meet the vendors minimum. So I don’t wanna do that. So I don’t have actually any dates now. I have been talking with doing a intensive POC boot camp, but, you know, I just got so much things going on in my life right now that I don’t think I could pull that together this fall. But in any case, if you need some training, you wanna send your people here, we can even start at, like, noontime and then end the final day at noontime so you can get your flights and travel and all that.

We’re one hour away from Albany, New York, and that’s a great little airport to fly in and out of. Actually, I’m flying out of it in November. They’ll go to a trade show, to interview vendors, vendors, product people. But in any case, I just wanna break in. There’s something about my company.

I don’t think I ever talked to you guys about much, and so I just wanted to insert it here since I’m sponsoring this episode and eating the cost to produce it. I wanted to share that with you. And now, I won’t be back until the end of the show, so please enjoy the rest of this episode. Send any feedback you have to me, and, we’ll talk to you at the end of the show.

Michael Bowne (PI): And it kinda works like this. So you have your IO Link device, which has an IODD file, which we mentioned earlier, that gets ingested by a parameterization tool. The parameterization tool comes with the IO Link master. Could be a separate piece of software. In some cases, could be a web page built into the IO Link master itself.

Depends on depends on the vendor. But then what happens after that, how that data goes from the IO Link master to the controller, the PLC, is fieldbus specific. So you have your own, fieldbus file, you know, GSD or EDS or ESI, whatever the case may be, which is ingested by the engineering tool of the of the PLC and kind of outside way outside the scope of of of IO Link. And so the EDS file, the GSD file, and and that is the that data then gets sent via fieldbus, and that’s the sum of all the IO Link device data from all the ports on the IO Link master, where that IO Link communication as as defined by the IODD file, configures the port for the master and for the devices. And so an IODD file is provided by the devices, and every device manufacturer must provide an IODD for their device.

It can be downloaded from the IODD finder, which is a website, and, it it describes what the entire device does. It describes the process data length, the process data structure, the parameter the name of the parameters, what range to expect, the data types, the addresses of the parameters in the in the in the indexes and subindexes. It can talk about GUI information, pages on which a parameter shall be displayed, names of parameter pages, all this kind of stuff is in an IODD file. It’s a it’s a zip file where you have that IODD as an XML. So that’s how we format the file.

So it’s it’s both and this is the key part, both machine readable and and human readable. It’s got a little picture of the device, picture of the manufacturer logo. And with your permission, maybe I can show the IODD finder. It’s, ioddfinder.io-link.com. Mhmm.

Looks simple enough. Let’s say we wanna look at a I’m gonna type in something here. Max ref. Let’s pick this. So this is just a this is a reference design, not an actual product that that, an end user would employ in their in their factory, but a reference design of something that maybe a device manufacturer would use.

And it’s shows the manufacturer name, the article name number, the product name, the device ID. All that stuff is ingested by the parameterization tool, which then uses that information to go up to this IODD finder and grab the IODD file shown here, which can be downloaded if you wanted to look at it yourself. But in the past few years, we implemented what’s called an IODD viewer, which is pretty cool, which takes that nice XML file and parses it. So in human readable form, if you wanted to compare quickly, hey. I’m an end user.

I wanna compare the IODD file from device vendor a to device vendor b to kinda see what kind of features they have. You could do that all very easily, and that’s shown here in the IODD viewer. What’s really what’s really neat about this IODD finder is that it has two ways it it it gets accessed. That’s this website that I just showed here. So as in humans are are accessing it, but it’s also accessible via API.

And we we track the the traffic to the Audi divider, and the vast, vast majority of the traffic comes via API. So these are IO Link masters that just had a device connected to them. Parameter is I’m sorry. Parameterization tool that has a you know, or connected to the IO Link master that had device connected them. They go up to the AudiD finder, and they pull down that IODD file for the device that was just connected so that now they they can be, configured.

And that’s really, really cool stuff. So all these IODD files are in one spot, in one database up there for for viewing or via the IODD viewer or for access from any number of IO Link tools out there.

Shawn Tierney (Host): So when we’re talking about API access, we’re talking about the tool we’re using to configure the master. So it could be a web page built into the master, or it could be a separate software program. Do I have that correct?

Michael Bowne (PI): Yeah. Right. So the parameterization tool, yeah, is usually is usually a software package that’ll run on your computer connecting to your, IO Link master that parameterizes the IO Link master. Yeah.

Shawn Tierney (Host): Excellent. Or

Michael Bowne (PI): through the network somehow. Maybe through the network. Yeah. Goes out and grabs that IODD file from the IODD finder to, you know, to parameterize that port in that device.

Shawn Tierney (Host): Which is excellent because in previous iterations of smart networks and smart devices, you always have to go searching a vendor’s website, and then people would get the wrong file, and then I would be in the field saying this is never gonna work because you get the wrong device file. If they can’t give you the right device file, you’ll never get it to work. You know? And so this is much better having the organization have everybody require everybody who has IO Link to put their IODD files in the one place so everybody can always find it. And so the software tools can find it automatically for you, which is just a huge a huge change versus what we went through in the nineties.

Michael Bowne (PI): Exactly. We came on a CD or something or what I mean, God only knows. I’m gonna switch gears a little bit here, talk about two topics subtopics within the IO Link domain, and one of them is IO Link wireless. This is, what we call is bridging the gap. So it’s an IEC standard, six eleven thirty nine as of November 2023,

Shawn Tierney (Host): and

Michael Bowne (PI): it’s enabling connections that simply weren’t possible before for IO Link. And in an example here, we’re showing a a smart machine tool where the IO Link sensor is integrated into the chuck of the lathe. Now that guy is spinning at 6,000 RPMs. That connection simply couldn’t be possible couldn’t be done any other way than with IO Link wireless or, let’s say, independent movers. So you’ve seen these moving systems where you’ve got the either floating or on a on a rail the other track systems exactly.

If you integrate the smarts of IO Link onto the movers themselves instead of using, SCARA or Delta robots to do the to I mean, that’s you’re saving huge amounts of cost Mhmm. That way if the if those guys can move on their own, and they use IO Link wireless to do that. Slip rings where certainly sending power, is is well known, but sometimes communication can be tricky via slip ring. Mhmm. Yeah.

End of arm tooling, like robot robot end of arms where you have a you’re gonna change the tool at the end of the arm. It’s more lightweight, saving on on robot cost that way. Less fewer lighter robots can be used, but it’s it’s, it’s cool. It the architecture looks pretty much the same, where you have your field level, your IO, and instead of wired connections, it’s it’s simply a wireless connection. Is that wired?

It’s it’s wireless. And and what’s different about IO Link Wireless is that it was built for industry. So I think in the past, people have been burned by wireless technologies that made some promises that didn’t maybe you know, they they couldn’t meet the the the the the rigorous environment and and requirements of of industry, but that was different. It was built for industry from the start. So it uses the two point two point four gig license free ISM band.

And what we do is a is this frequency hopping so that we use the same IO link, you know, data structure. We do this frequency hopping, and it’s it’s a cycle of five milliseconds. So you’re not going to get that one millisecond time that you get via wired IO link. We do a five millisecond cycle time, and then it’s using this frequency hopping method. It’s basically cable grade, connection, 10 to the minus nine error probability.

You can have hundreds of wireless devices in a machine, and it’s deterministic. It’s designed it is designed from the outside for both for control, of course, but, of course, also for for monitoring and maybe, like, a brownfield. You wanna you can’t get IO Link to a sensor or something that you can maybe use IO Link wireless to get access to some some hard to reach sensor.

Shawn Tierney (Host): Well, you know, I thought that I think this is so interesting. We actually had a company on, I think, a year or two ago, who does IO Link wireless, and that was the first time I had heard of it. And he said, yeah. Hundreds of devices. Right?

It’s pretty amazing, especially if you have a lot of a lot of things, the smart devices that need to be, you know, free from the network, need to be wireless. Maybe, you know, the slip ring communications has been a problem for years and years. This because this is frequency hopping, it eliminates a lot of the, problems with, you know, interference. Right?

Michael Bowne (PI): Yeah. Right.

Shawn Tierney (Host): Exactly. And and, you know, it’s just and I I highly recommend people look into this if you’re if you’re challenged. You can’t run a wire to every sent every sensor or every device. This is definitely some very interesting technology.

Michael Bowne (PI): And just like with, so we we I I didn’t mention it explicitly, but when we’re talking about IO Link wiring, there’s a 20 meter limit Mhmm. For wired IO Link. And we, you know, we talk about the same thing for IO Link wireless that you’re not gonna be going hundreds of meters wireless, via via via IO Link wireless. So we we stick to that 20 meter limit for IO Link wireless as well.

Shawn Tierney (Host): Great for a cell. Great for a robot. Great for a robot tools. Right? But, yeah, this is not gonna replace your Wi Fi or your LTE or anything like that.

Michael Bowne (PI): Yeah. If you’re or if you’re in a, you know, a tank farm or something, you’re not going long distances Mhmm. Across across a a plant like that. Alright. In the last couple minutes, one more thing I wanna talk about.

This is pretty new. That’s you’re not gonna find devices out or at least many devices out on the network like this, but this is functional safety for IO Link. So IO Link safety is really clever name. IO Link safety because today, you’ve got if you wanna do functional safety, you’ve got your FSCPs or your functional safety communication protocols like FSOE or SIP safety or PROFIsafe, whatever the case may

Shawn Tierney (Host): be. Mhmm.

Michael Bowne (PI): You connect it out to your remote IO, but every single device needs a different interface. If it’s a relay, it needs a maybe a DO. If it’s a estop, it needs a DI. If it’s a analog signal, it needs its own functional safe, analog input. With IO Link safety, we can get rid of all those separate interfaces.

Just use IO Link for that, for any kind of safety measure functional safety measuring sensor, functional safety switching device. Maybe if the drive has a safe input on it that it that it that it could use, all that can be done with a functionally safe IO Link master and IO Link safety. And, it’s it’s the same concept as as IO Link where we’re transmitting this data via IO Link, but we transmit both safety and standard data from a device. You can migrate, IO Link safety and OSSD, so output switching signal devices can be done in the same product. The masters also offer generic IO Link standard operation.

They also they offer the OSSD mode. And it’s cool because you don’t need any switches for safety addressing. The the watch log time is set automatically. You can exchange devices without a specific tool just like with regular IO Link, and then it’s just that regular IO Link connection of 20 meters, flexible, no shielding, inexpensive. And this is this is pretty new stuff.

We just just and I’m talking, like, this month, got the the TUV, the TUV certification for IO Link safety. So we’re we’re expecting this to ramp up quickly over the next couple of years again for the same reason that IO Link, grew so so fast, and that’s the no comp no competitor, and, you know, you’re saving on a lot a lot of costs by by using it.

Shawn Tierney (Host): Does it simplify the wiring? Because in your photo on the screen, you show the safety sensor with the two, let’s say, two, relays. Right? Mhmm. And, you have to acquire both of those up to the to the input, the safety input.

Right? Functional safety digital in. With IO Link safety, are we running just one cable?

Michael Bowne (PI): Just one cable. Yeah. It’s the same same IO Link cable. Exactly. Yeah.

Shawn Tierney (Host): So just like with, let’s say, SIP safety or a PROFIsafe, where you’re still just running one Ethernet cable. Mhmm. Here, we’re just running one IO link cable. So you’re you are simplifying installation, I think.

Michael Bowne (PI): Yeah. And it’s and and it uses some of the similar concepts, mainly that that whole, black channel principle, that we know from all that all the that all the functionally safe, protocols use that, what you care about is making sure that that signal gets from one end to the other. Now it’s a whole heck of a lot easier with IO Link because IO Link is point to point, not going over a network. So, that that becomes a whole heck of a lot easier, but it’s yeah. That’s great.

I mean, it’s just one one wire. You you don’t have to okay. Did I plug it in? You know? Is it normally open, normally closed?

Do you have both? Do you have three of them? It’s just that one IO Link connection. Alright. I think I’ll wrap it up quickly here.

So a lot of this focused on end users, people installing IO Link in their machines or in their in their factories. But for the if any listeners are sensor manufacturers, device manufacturers, there are really two main ways to get an IO Link device certificate. There’s, the membership route, and then there’s a license model for those that may, for whatever reason, choose not to become a member. And, with the license model, you I’ll start on the right hand side to work backwards. You implement IO Link, request the test in an IO Link test center, then you get your IO Link vendor ID from PI, and then you get your product tested at the test center.

And then every device has a manufacturer declaration. And when I mentioned the IODD finder before, when when a device manufacturer uploads that IODD file to the IODD finder, they also at least in the last couple of years, we’ve we’ve we’ve asked and required them to do that. They also upload the manufacturer declaration. So end users can see, hey. The manufacturer has tested this device, certified, and, and they can rest assured that it’s it’s gonna work as specified per per the IO Link specs and standards.

And then in the in the license model, you gotta purchase a license per device and acquire patent rights. Just about nobody goes this route, but it was initiated for political reasons. Some companies or company, didn’t wanna join PI, but just about nobody, does that. And most go the membership model route where you join, get your IO Link vendor ID, implement IO Link, and then we allow members to self test using any number of testers that are out on the market. And then you can sign the manufacturer declaration yourself, which is basically self certification.

If you wanna learn more, these slides were taken from a slide deck that’s presented couple times throughout the year at an IO Link one day workshop. And this is a this is a a very special Shawn Tierney, resource. We don’t, you know, display this everywhere. But if anybody wants to get access to this stuff, they can go to, io-link.us/2020five. It’ll ask for a little password.

The password is twenty twenty five, and you can download the the training class manual, the so, the full slide deck that is that is performed and and really demonstrated at these IO Link workshops. So like I said, we do four of these throughout the year. We did two already, one in Seattle, one in Philly, Philadelphia, and then we’ve got two coming up in October, one in Vancouver, British Columbia, and one in Richmond, Virginia. So if anybody’s listening and and in those areas, it’s a free class. You get lunch.

You get a day of learning all about IO Link. We do a lot a lot of demonstrations. We get down into the the bits and bytes a little bit. And then what’s cool is at these events, a bunch of vendors, maybe a dozen or so show up with products. So if you wanna walk the room, it’s kinda like a little bit of a micro fair, and they support the event, which is how end users are able to come and get a free class and get a free lunch.

So go to iolink.us/events. And if you’re in in those areas, we welcome you to to join us at at one of these classes. And that’s my that’s my plug. Yeah.

Shawn Tierney (Host): Yeah. And I I just wanna focus in on this for those who are driving. So Vancouver, British Columbia, October 1.

Michael Bowne (PI): Oh, yeah. Yeah.

Shawn Tierney (Host): Richmond, Virginia. Right? East Coast people. October 28 in i0-link.us/events. So just wanted to say that again because sometimes they’re driving, they’re like, well, I didn’t hear it or you know?

So, hey. Look. If you’re on the East Coast with me and you’re near Richmond, October 28, sign up early. Don’t sign up often. Just sign up once.

But but, you know, if you have friends you wanna meet there, you don’t have them do that. And, it’s great that the vendors come and make the events possible. Yeah. And it’s it’s nice just to get that one out. So many so many of us are so busy.

It’s nice to get that one on one with the vendors. I’ve actually been with the vendors at these shows, and it’s the the audience that it’s attendees usually have some awesome questions. And a lot of times, they ask you about things not even related to it, but, you know, they just see you, so they wanna talk to you. So definitely wanna shout out to all the vendors who are gonna be there as well.

Michael Bowne (PI): Yeah. It’s it’s it’s it’s a great I mean, it’s learning. It’s it’s product if you want it to be, but the content like this, is it’s not salesy at all. I mean, it is a it’s an it is an educational event.

Shawn Tierney (Host): But if

Michael Bowne (PI): you do wanna talk to the vendors, then that’s that’s great. They’re there to help you out. Because at the end of the day, you can’t you can’t buy an IO link. Right? I mean, it it’s just a standard.

It’s just a what you can buy are the products that use it. And so that’s why, we work together with the vendors to to do to put these events on. Yeah. It’s awesome. Yeah.

And they’re and they’re I mean, it’s it’s really impressive that they’re willing to get in a room with, really, their competitors and and do this and put this together. The last one I wanna mention is profuse news, but we talked about that at the beginning. This is that monthly newsletter that we that we send out to 130,000 of our closest friends, and maybe you’re receiving PROFINews. If not, you can go to the website. It’s simply profinews.com and, subscribe to PROFINews, where those new products, particularly IO Link products are mentioned and and, and highlighted.

Shawn Tierney (Host): Yeah. One thing I like about this is, you know, if you get too much email like me from sources you don’t want it from, You know, it’s nice that you can go to the website and pull it down when you wanna see it. Right? So so maybe it’s you’ve been a couple months. You wanna see what’s new on IO Link.

You can go up there. Their website is excellent. You can go and look at all the articles, all the different, new products that have come out. And you don’t have to if you you know, I know a lot of people like the newsletter subscriptions. I’m one of those, Gen x’s who don’t, and and it’ll at least you know, I want, like like, I wanna hear from Michael.

I wanna hear from Tom. I wanna hear from students like Daniel I was emailing yesterday. You know, I’d I’d every vendor, there’s, you know, hundreds we follow. If I had a newsletter from each of those, it would my inbox would be full. So but in any case, it’s excellent, guys.

It’s it’s no fluff. It’s really. And and I’ve discovered new vendors from just following that list. You know? These people I didn’t didn’t know from my past.

And, in any case, highly recommend you guys all check it out at least once or twice a year if you don’t want the email.

Michael Bowne (PI): I appreciate that. Yeah. And, like and and like I said and and right there at the top, there’s a button that says product news. Click that, and then there’ll be every month’s worth of new products section article that we published

Shawn Tierney (Host): for our newsletter. There’s some great articles up there too. So, thank you very much for publishing them, and keep up the great work on those. I know we enjoyed them during the couple years I was doing the news. We would, go up there on a regular basis.

Michael Bowne (PI): We’re gonna send out issue number 251, next week.

Shawn Tierney (Host): Oh, wow.

Michael Bowne (PI): So every month, that’s, you know, do the math. Twenty years worth of crazy. Crazy.

Shawn Tierney (Host): Job. Good job. Keep it up.

Michael Bowne (PI): That’s all I got. Once again, thanks thanks for having me, Shawn.

Shawn Tierney (Host): Michael, I really appreciate you coming on, and that was a great update. And thank you for including some real technical details in there. We will be, using the opportunity of having this episode to go ahead and, cover more IO Link products. So, we have had a number of vendors send us products, but with non sponsored products. So it’s it’s hard to find time to use things when when, know, everybody says, well, play with it in your free time.

I think we’ve all heard that. And, but in any case so we have new lessons coming. We have new videos coming. We have new demos coming. So stay tuned, folks.

But, again, Michael, thank you so much for coming back on the automation podcast. Let’s not wait four years. Let’s say you’re back on in a few months to talk about MTP and, because I think that’d be cool and then maybe Noah later on. Yeah. But thanks again for coming on the show.

Really appreciate it.

Michael Bowne (PI): Oh, my pleasure. My pleasure.

Shawn Tierney (Host): Well, I hope you enjoy this episode, and I wanna thank Michael for coming on the show and bringing us up to speed on IO Link. We hope to get Michael back on in the coming months to talk about MTP and Noah, and some of the other things that they’ve added to their portfolio since we had them on four years ago. But with that said, I also wanna thank all the members out there who’ve joined my membership program. I look forward to today where we can grow that above the two to 3% mark and actually start doing content dedicated for, what the members are asking for. Right?

So you guys can ask, hey. Cover this, cover that, and we can actually afford to do that. So thank you all the members out there. I know you just love to support the channel, and, you know, you really are very busy like most of us are. So, in any case, I just wanted to take a minute to thank you.

And I also wanna thank all my students over at the Automation School. Did you know I’ve added a bunch of new, lessons lately? So especially to the POC classes. So in any case and I got a bunch more planned this fall and a lot planned on IO Link. So you’re gonna see a lot of content from me at IO Link, both on the lunchtime show that I’ve been doing, as well as in some upcoming episodes of the automation show and the automation minute.

So, it’s something I’ve wanted to do for a long time, and the stars are just aligned. So, we’ll be covering IO Link a lot both on the blog, on the channel, and over at the automation school as well. And with that, that’s all I got to say. Thank you very much for making it to the end of the show. I wanna wish you all good health and happiness.

And until next time, my friends, peace.

Until next time, Peace ✌️

If you enjoyed this content, please give it a Like, and consider Sharing a link to it as that is the best way for us to grow our audience, which in turn allows us to produce more content 🙂

Shawn M Tierney

Technology Enthusiast & Content Creator