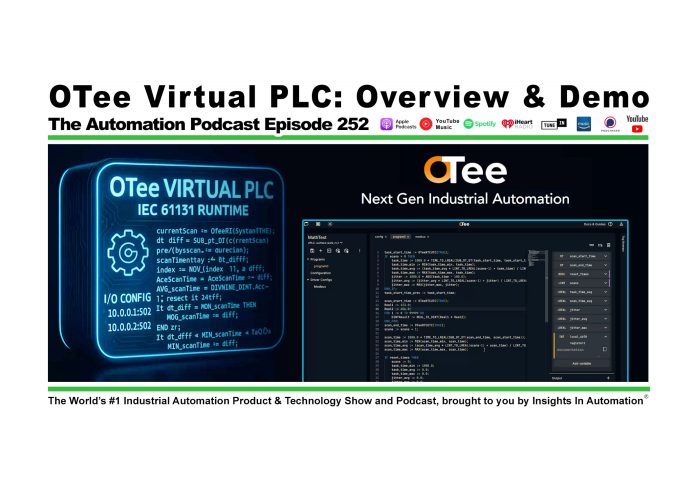

Shawn Tierney meets up with Henrik Pedersen and Jacob Abel to learn about OTee Virtual PLCs in this episode of The Automation Podcast.

For any links related to this episode, check out the “Show Notes” located below the video.

Listen to The Automation Podcast from The Automation Blog:

Podcast: Play in new window | Download

The Automation Podcast, Episode 252 Show Notes:

Special thanks to Henrik Pedersen and Jacob Abel for coming on the show, and to OTee for sponsoring this episode so we could release it “ad free!” To learn about the topics discussed in this episode, checkout the below links:

Read the transcript on The Automation Blog: (automatically generated)

Shawn Tierney (Host): Thank you for tuning back into the automation podcast. Shawn Tierney here from Insights. And this week on the show, I meet up with Henrik Pedersen and Jacob Abel to learn all about virtual PLCs from OTee. That’s o t e e. And, I just thought it was very interesting.

So if you guys have ever thought about maybe running virtual PLCs to test some processes out, I think you’ll really enjoy this. With that said, I wanna welcome to the show for the very first time, Hendrik and Jacob. Guys, before we jump into your presentation and learn more about what you do, could you first introduce yourself to our audience?

Henrik Pedersen (OTee): Yeah. Sweetly. So my name is Hendrik. I am the cofounder, COO, OT, a new industrial automation company, that, we’re really glad to present here today. I have a background from ABB.

I worked eleven years at ABB. In terms of education, I have an engineering degree and a master degree in industrial economics. And, yeah, I’m I’m excited to be here. Thanks, Rom. And I’ll pass it over to Jake.

Jacob Abel (Edgenaut): I’m, Jacob Abel. I’m the principal automation engineer at Edgnot. EdgeNaught is a systems integrator focusing on edge computing and virtual PLCs. My background is in mechanical engineering, and I’m a professional control systems engineer, and I have thirteen years experience in the machine building side of industrial automation, specifically in oil and gas making flow separators. And I’ll hand it back to Henrik here.

Henrik Pedersen (OTee): K. Great. So OT, we are a a new industrial automation company, the new kid on the block, if you will. We’re a start up. So, we only started, about three years ago now.

And, we focus solely on virtual PLCs and and the data architectures allow you to integrate virtual PLCs in in operations. And, you know, some of the listeners will be very familiar with this first, thing I’m gonna say, but I think it’s valuable to just take a take a little bit step back and and remember what has happened in in history when when it comes to to IT and OT and, and and what really what really happened with that split. Right? So it was probably around the ‘9 you know, around nineteen nineties where the the the domain computer science were really split into these two domains here, the IT and OT. And, and that, that was, that was kind of natural that that happened because we got on the, on the IT side of things, we got Internet, we got open protocols and, you know, we had the personal computers and innovation could truly flourish on the IT side.

But whereas on the OT side, we were we were kind of stuck still in the proprietary, hardware software lock in situation. And and that has that has really not been solved. Right? That that that is still kind of the the situation today. And it this is what this is obviously what also, brought me personally to to really got really super motivated to solve this problem and and really dive deep into it.

And I experienced this firsthand with with my role in NAD and, how how extremely locked we are at creating new solutions and new innovation on the OT side. So so we’re basically a company that wants to to truly open up the the the innovation in this space and and make it possible to adopt anything new and new solutions, that that sits above the PLC and and, you know, that integrate effectively to to the controller. So I I have this this, you know, this slide that kind of illustrates this point with with some some, you know, historical events or or at least some some some big shifts that has happened. And, Aurene mentioned a shift in nineteen nineties. And it wasn’t actually until ’20, 2006 that Gartner coined this term OT, to explain the difference really what what has happened.

And and, you know, as we know, IT has just boomed with innovation since since the nineties and OT is, is, is slowly, slowly incrementally getting better, but it’s still, it’s still the innovation pace is really not, not fast. So, this is also, of course, illustrated with all the new developments in in GenAI and AgenTic AI, MCP, and things like that that is kinda booming on on the IT side of things. And and and yeah. So, but we do believe that there is actually something happening right now. And and we have data that they’re gonna show for for that.

Like, the the large incumbents are now working on this as well, like virtual PLCs, software defined automation and all kinds of exciting things going on on the OT side. So we do believe that that we will see, we will see a shift, a true big shift on the OT side in terms of innovation, really the speed in which we can, we can improve and adopt new solutions on the OT side. And this is kind of exemplified by, like, what what is the endgame here? Like, you could say that the endgame could be that IT and OT once once again becomes the same high paced innovation domain. Right.

But then we need to solve those underlying problems, the infrastructural problems that are still so persistent on the OT side of things. The fine point of this slide is to just illustrate what’s happening right now. It’s like cloud solutions for control is actually happening. Virtual PLC, software based automation, AI is happening all at once. And we see it with the big suppliers and and also the exciting startups that’s coming into this space.

So I think there’s there’s lots of great excitement now that we can we can expect from the OT side, in in next few years.

Shawn Tierney (Host): Yeah. You know, I wanna just, just for those listening, add a little, context here. If we look at 1980, why was that so important? Why is this on the chart? And if you think about it, right, we got networks like Modbus and, Data Highway in nineteen seventy eight, seventy nine, eighty.

We also got Ethernet at that time as well. And so we had on the plant floor field buses for our controls, but in the offices, people were going to Ethernet. And then when we started seeing the birth of the public Internet, right, we’re talking about in the nineties, people who are working on the plant floor, they were like, no. Don’t let the whole world access by plant floor network. And so I think that’s where we saw the initial the the divide, you know, was 1980.

It was a physical divide, just physically different topologies. Right? Different needs. Right? And then and and as the Internet came out in the early nineties, it was it was now like, hey.

We need to keep us safe. We know there’s something called hackers on the Internet. And and I think that’s why, as you’re saying in 2006, when Gartner, you know, coined OT, we were seeing that there was this hesitant to bring the two together because of the different viewpoints and the the different needs of both systems. So I think it’s very interesting. I know you listeners, you can’t see this, but I kinda want to go back through that and kinda give some context to those early years.

And and, you know, like Henrik says, you know, now that we’re past all that, now that we’re using Ethernet on the plant floor everywhere, right, almost everywhere, on all new systems, definitely, that that becomes the right now on this on the today on the, on the chart. And I’ll turn it back to you, Henrik.

Henrik Pedersen (OTee): Yeah. I’ll search that. I just wanna echo that as I think that there are really good reasons for why this has happened. Like, the there has you could argue that innovation could flourish on the IT side because there was less critical systems, right, less, more, you know, you can do to fail fast and you can do, you can test out things on a different level. And so so there’s really lots of good reasons for why this has happened.

We do believe that right now there is some really excitement around innovation, the OT side of things and and this pent up kind of, I wouldn’t call it frustration, but this pent up potential, I think is the right word, is is can be kind of unleashed in our industry for for the next, next decade. So so we are like this is really one of the key motivators for me personally. It’s, like, I truly believe there’s something truly big going on right now. And and I I do I do encourage everyone, everyone listening, like, get in get in on this. Like, this is happening.

And, you know, be an entrepreneur as well. Like, build your company, build and, you know, create something new and exciting in this space. I think I think this is this is a time that there hasn’t been a better time to create a new new technology company or a new service company in this space. So this this, this is something at least that motivates me personally a lot. So let me move over to kind of what we do.

I mentioned I mentioned that we focus solely on the virtual PLC. This this is now presented in the slide for those that are listening as a as a box inside a open hardware. We can deploy a virtual PLC on any, ARM thirty two thirty two and and sixty four bit processor and x eighty six sixty four bit with the Linux kernel. So so there are lots of great, options to choose from on the hardware side. And and, and yeah.

So you can obviously when you have a Virtual PLC you can think of it new in terms of your system architecture. You could for instance, you know deploy multiple Virtual PLCs on this on the same hardware and you can also, think about it like you can use a virtual PLC in combination with your existing PLCs and could work as a master PLC or some kind of optimization deterministic controller. So it’s it’s really just opening up that, you know, that architectural aspect of things. Like you can think new in terms of your system architecture, and you have a wide range of hardware to choose from. And, and yeah, So the the flexibility is really the key here, flexibility in how you architect your system.

That CPU that you deploy on will will obviously be need to be connected to to the field somehow, and that’s that’s true, classical remote IO, connections. So we currently support, Modbus TCP and Ethernet IP, which is kind of deployed to to, our production environment, as it’s called. So moving on to the next slide. Like, this is kind of the summary of our solution. We have built a cloud native IDE.

So meaning anyone can can basically go to our website and log in to into the solution and and give it a spin. And, we’ll show you that afterwards with with Jake. And the system interacts through a PubSub data framework. We use a specific technology called NUTS, for the PubSub communication bus. And you can add MQTT or OPC UA to the PubSub framework, according to your needs.

So, and from that, you can integrate with, whatever whatever other, software you might have, in your system. So we have these value points that we always like to bring up. Like, this obviously breaks some kind of vendor lock in in terms of the hardware and the software. But it’s also, our virtual PLC is based on on the six eleven thirty one. So it’s not a lock in to any kind of proprietary programming language or anything like that.

There is, there’s obviously the cost, element to this that you can potentially save a lot of cost. We have, we have verified with with with some of our customers that they estimate to save up to 60% in total cost of ownership. This is there is obviously one part is the capex side and the other part is is the opex. And and is this data framework, as I mentioned, is in in in which itself is is future proof to some extent. You can you can integrate whatever comes comes in in a year or or in a few years down the line.

And, there’s environmental footprint argument for this as you can save a lot on the on the infrastructure side. We have one specific customer that estimates to save a lot on and this this particular point is really important for them. And then final two points is essentially that we have built in a zero trust based security, principle into this solution. So we have role based access control. Everything is encrypted end to end, automatic certification, and things like that.

The final point is, is that this is the infrastructure that allows you to bring AI and the classical, DevOps, the the thing that we’re very used to in the IT side of things. Like, you you commit and merge and release, instead of, instead of the traditional, way of working with your automation systems. So I know this is like, this is pro pretty much, like, the boring, sales pitch slide, but, but, yeah, I just wanted to throw this this out there for for the guys that there is some there is some, intrinsic values underneath here. The way the system works, you will you will see this very soon, through the demo, but it’s basically you just go to a website, you log in, you create a project. In there, you would create your your PLC program, test, you code, you simulate.

You would onboard a device. So onboard that Linux device that you you want to deploy on. This can be as simple as a Raspberry Pi, or it can be something much more industrial grade. This depends on on on the use case. And then you would deploy services like, as I mentioned, MQTT and OPC UA, and then you would manage your your your system from from the interface.

And, I have this nice quote that we got to use from one of the customers we had. This is a global, automotive manufacturer that, basically tells us that it’s, they they highlighted the speed in which you can set this up, as as one of the biggest values for them, saving them a lot of hours and setting setting up the system. So I also wanted to show you a real you know, this is a actual real deployment. It was it was deployed about a year ago, and this is a pump station, or a water and wastewater operator with around 200 pump stations. They had a mix of of Rockwell and Schneider PLCs, and they had a very high upkeep, and they were losing a lot of data from these stations because they were connected over four g.

When the Internet was a bit poor, they lost a bit of data in their SCADA systems, so they had these data gaps and things like that. So pretty pretty, you know, standard legacy setup to be to be honest. Quite outdated PLCs as well. So what they what they did for the first, pump station was they they, you know, removed the PLC. They put in a Raspberry Pi for for, like, €60 or, like, $70, connected it to to a to a remote IO Ethernet IP module they had, in in the storage, and deploy this data framework as I’m showing on the screen now.

So so they that was that was the first station they put online, and they they chose a Raspberry Pi because they thought, okay, this is interesting, but will it work? And then they chose a pump station, which was was really just poor from before. So they had very little to to to lose to to deploy on this station. So so, yeah, this has been running for a year now without any any problems on a Raspberry Pi. We have obviously advised against using a Raspberry Pi in a critical environment, but they just insisted that that what that’s what they wanted to do for this first case.

Shawn Tierney (Host): And I’ll back that up too. Your generic off the shelf Raspberry Pi is just like a generic off the shelf computer. It’s not rated for these type of environments. Not that all pump houses are really bad, but they’re not air conditioned. And I think we’ve all had that situation when it’s a 120, 130 out that, you know, off the shelf computer components can act wonky as well as when they get below freezing.

So just wanted to chime in there and agree with you on that. For testing, it’s great. But if you’re gonna leave it in there, if you were in my town and you say you’re gonna leave that in there permanently, I would ask to have you, assigned somewhere else for the town.

Henrik Pedersen (OTee): Yeah. Yeah. Exactly. No. So and and that point is also illustrated with the second station they brought online.

So there they chose a much more industrial grade CPU, that, that, was much, you know, cost cost a bit more, but it’s more suited for the environment. And, and yeah. So this was, I can disclose it was a Bayer Electronics, CPU. So so yeah. And, and they reported, some good, good metrics in terms of, like, the results.

They they said around 50 on the hardware, 75% on the management of the PLC system. So this relates more to that they have very a lot of, you know, driving out with the car to these stations and doing changes to their systems and, and updates. They no longer have any, any data loss. It’s local buffer on the data framework. They’ve increased tag capacity with 15 x, resulting in in four fifty five x better data resolution and a faster scan frequency.

And this is actually on the Raspberry Pi. So so just just think of it as as the the even the even the, kind of the lowest quality IT off the shelf, computers, are are able to to, to execute really fast in in in, or fast enough for for, for these cases. So, Shawn, that was actually what I wanted to say. And, and also, you know, yeah, we are we are a start up, but we do have, fifth users now in 57 different countries across the world. And it’s it’s really cool to see our our our, our technology being deployed around the world.

And, and yeah. I’m really, really excited to to, to get more, users in and and hear what they what they, think of the solution. So so yeah. I’ll I’ll with that, I don’t know if, Shawn, you wanna you shoot any questions or if we should hand it over to Jake for for for a demo.

Shawn Tierney (Host): Yeah. Just before we go to Jake, if somebody who’s listening is interested, this might be a good time. It said that, you already talked about being cloud based. It’s, o t e e. So Oscar Tom, Edward Edward for the the name of the company.

Where would they go if if they like what Jake’s gonna show us next? Where will they go to find out more?

Henrik Pedersen (OTee): Yeah. So I would honestly propose that they just, reach out to to me or Jake, on on one of the QR codes that we have on the presentation. But they can also obviously go to our website, 0t.io,0tee.io, and just, either just, log in and test the product, or they could reach out to us, through our website, through the contact form. So yeah.

Shawn Tierney (Host): Perfect. Perfect. Alright, Jake. I’ll turn it over to you.

Jacob Abel (Edgenaut): Thanks, Shawn. Fantastic stuff, Henrik. I wanna take a second too to kinda emphasize some of the technical points that you, presented on. Now first, the the fact that you have the built in zero trust cybersecurity is so huge. So, I mean, the OT cybersecurity is blowing up right now.

So many certifications, you know, lots of, consulting and buzz on LinkedIn. I mean, it’s a very real concern. It’s for a good reason. Right? But with this, zero trust built in to the system, I I mean, you can completely close-up the firewall except for one outgoing port.

And you have all the virtual PLCs connected together and it’s all done. You know, there’s no incoming ports to open up on the firewall to worry about, you know, that security concern. You know, it’s basically like, you know, you’ve already set up a VPN server, if you will. It’s it’s not the same, but similar and, you know, taking care of that connection already. So there’s an immense value in that, I think.

Shawn Tierney (Host): And I wanted to add to the zero trust. We’ve covered it on the show. And just for people, maybe you’ve missed it. You know, with zero trust is you’re not trusting anyone. You authorize connections.

Okay? So by default, nobody’s laptop or cell phone or tablet can talk to anything. You authorize, hey. I want this SCADA system to talk to this PLC. I want this PLC to talk to this IO.

I want this historian to talk to this PLC. Every connection has to be implicitly I’m sorry. Explicitly, enabled and trusted. And so by default, you know, an an integrator comes into the plant, he can’t do anything because in a zero trust system, somebody has to give him and his laptop access and access to specific things. Maybe he only gets access to the PLC, and that makes sense.

Think about it. Who knows whether his laptop has been? I mean, we’ve heard about people plug in to the USB ports of the airport and getting viruses. So it’s important that person’s device or a SCADA system or a historian only has access to exactly what it needs access to. Just like you don’t let the secretary walk on the plant floor and start running the machine.

Right? So it’s a it’s an important concept. We’ve covered it a lot. And and, Jake, I really appreciate you bringing that up because zero trust is so huge, and I think it’s huge for OT to have it built into their system.

Henrik Pedersen (OTee): Yeah. Absolutely. Absolutely.

Jacob Abel (Edgenaut): I wanted to highlight too the Henrik mentioned that the the backbone of the system is running on a technology called NATS. That’s spelled n a t s. And why that’s important is this is a a lightweight messaging, service, and it’s designed to send millions of messages per second. You know, that’s opposed to, you know, probably the best Modbus TCP device that you can find. You might get a couple 100 messages through per second.

It’s millions of messages per second. It’s, you know, especially with, you know, we’re dealing with AI machine learning, you know, training models. I mean, we’re data hungry. Right? So this gives you the backbone too.

You know, it’s like it can push an immense amount of tag data, you know, with ease. I think that’s another really important point. With that, though, I’ll I’ll get on to the demo.

Henrik Pedersen (OTee): Oh, that’s great. We do we do see that, Jay, that most of our customers report on that, you know, 400 or 700 x better data resolution. And so it’s it’s a step change for for for the data resolution there. Yeah.

Jacob Abel (Edgenaut): Excellent. So one of the things that I personally love about OT is how quickly you can get into the PLC once everything’s set up. So this is OT’s website, obviously, ot.io. So once you’re here, you just go to log in. And that brings in the login screen.

Now I’m are I’m using my Google account for single sign on, so I can just click continue with Google. And this brings me into the main interface. And another thing that I love is that, you know, it is very simple and straightforward, you know, and simple is not a bad thing. Simple is a good thing. I mean, the way that things should be is that it should be, it should be easy and the finer details are taken care of for you.

So right here, we have our main project list. I just have this one benchmarking program that I’ve imported in here. And you also have device lists, just a a test device that I’ve installed the runtime on. Just real quick. You know, you have a Martha, the AI assistant in the corner here.

And, the documentation guides is up here. So you can get help or look into reference material very easily. It’s all right there for you. So I’m gonna open up this program here. So just a quick tour here.

Right up here in the top left is basically where where most everything’s done. So if you click on this little down arrow, you can choose what virtual PLC runtime to attach it to. I’ve already attached it to the device. I installed the runtime on. You can add, you know, a new program, driver, function blocks, custom data types real quick here.

Compile your program, download it to the device. Check the release history, which is really, really great. As you can, you can go into release history and you can revert to a prior version very easily. We got built in, version control, which is another, great feature.

Henrik Pedersen (OTee): I can also just comment on that, Jake, that we do have we do have, in the quite short term roadmap to also expand on that with Git integration, that, a lot of our customers are are asking for. So yeah.

Jacob Abel (Edgenaut): Awesome. Yeah. I mean, that’s that’s another, very hot topic right now. It’s, you know, getting getting the revision control systems, as part of, you know, at least the textual, programming languages. See, so, you know, we have a few, like, housekeeping things here.

I mean, you can delete the program, export it. It’s a good good point here is that, OT complies with the PLC open, XML specification. So you can import or export programs, in this XML format, and it should work with solid majority of other automation software out there. You know, if you need to, you want to transition over to OT, you know, you can export it from your other software and import it rather easily. Got your program list here and, you know, just the basic configuration of, you know, you can add global variables that you wanna share between the different programs and POUs or, you know, change the, cycle rate of the periodic tasks, add more tasks.

Let’s just get jump into this program here. Both the system uses the IEC sixty one one thirty one dash three standard structured text. So here’s just a little, quick benchmark program that I’ve been using to do some performance testing. Like you, you have the, the code right here, obviously. And on our, our right, the variable list, very easy to add a new variable and pick out the type.

You can set a set of default value, add some notes to it. Super easy. So let’s go online. So if you have these little glasses up here in the top, right, you display live tag values. And so it’s grabbing from the runtime that’s running and plopping it right in here in the editor, which I I love the way it’s displayed.

It makes it. And, you know, it’s one of the question marks is if you’re doing structured text instead of letter logic, like how it’s gonna show up and how readable is it gonna be. I think the, the text, like the color contrast here helps a lot. It’s very, very readable and intuitive. And we also have the tag browser on the right hand side.

Everything is, organized into, you know, different groups. There’s the the resources and instances that you’ve set up in the configuration tab. So the by default, the tag the tags are all listed under there. And here too, you know, you can set tag values doing some performance testing, as I said. So this is, recording some some jitter and task time metrics.

And that’s that’s really it. That’s the that’s the cloud IV in a nutshell. Super easy, very intuitive. I mean, it’s there there’s zero learning curve here.

Shawn Tierney (Host): For the, audio audience, just a little comment here. First of all, structured text to me seems to be, like, the most compatible between all PLCs. So, you know, everybody does ladder a little bit differently. Everybody does function blocks a little bit differently. But structured text and, again, I could be wrong if you guys think out there in the in listening, think I’m wrong about that.

But when I’ve seen structured text and compared it between multiple different vendors, it always seems to be the closest from vendor to vendor to vendor. So I can see this makes a great a great place to start for OT to have a virtual PLC that supports that because you’re gonna be able to import or export to your maybe your physical PLCs. The other thing is I wanted to comment on what we’re seeing here. So, many of you who are familiar with structured text, you know, you may have an if then else, or an if then. And and you may have, like, tag x, equals, you know, either some kind of calculation, you know, maybe, you know, z times y or just maybe a a constant.

But what we’re seeing here is as we’re running, they have inserted at a in a different color the actual value of, let’s say, tag x. So in between you know, right next to tag x, we see the actual value changing and updating a few times a second. And so it makes it very easy to kinda monitor this thing while it’s running and see how everything’s working, and I know that’s that’s huge. And I know a lot of vendors also do this as well, but I love the integration here, how it’s so easy to see what the current values are for each of these variables. And, I’ll turn it over to you, Hendrick.

I think I interrupted you. Go ahead.

Henrik Pedersen (OTee): Yeah. No. I was just gonna comment on that. Jake said, like, this is the this is the POC editor, and the next the next big feature that we’re releasing very soon is essentially the service, manager, which is the, which is the feature that will allow our users to deploy any kind of service very efficiently, like another runtime or OPC UA server or an entity server or or or whatever other, software components that that, you want to deploy, like a Knox server or things like that. So and that’s that’s, we were really excited about that because, that will kind of allow for a step change in how you kind of orchestrate and manage your system and your, your system and your, your, you have a very good overview of what’s going on with versions of, of the different software components running in your, your infrastructure and your devices and things like that.

So we’re really excited about that, that it’s coming out. And it might be that actually when when this, episode airs, who knows if it’s if it’s done or or not, but we’re very close to release the first version of that. So excited about that.

Shawn Tierney (Host): Now I have a question for you guys, and maybe this is off topic a little bit. So let’s say I’m up here in the cloud. I’m working on a program, and I have some IO on my desk I wanna connect it to. Is that something I can do? Is there a connector I can download and install my PC to allow the cloud to talk to my IO?

Or is that something where I have to get a a, you know, a local, you know, like we talked about those industrial Linux boxes and and test it here with that?

Henrik Pedersen (OTee): Yeah. So I think you what you what you’re you’re after is, like, the IO configuration of, if you wanna deploy a driver, right, or, like, a modbus driver and how you figure out the system. Right?

Shawn Tierney (Host): Yeah. Because this is in the cloud. It’s not on my desk. The IO is on my desk. So how would I connect the two of them?

How would I is is that something that can be done?

Henrik Pedersen (OTee): Yep. Yeah. Exactly. That’s that’s actually the you know, I I think, Jake, you might just wanna show why you deploy a driver. Right?

Jacob Abel (Edgenaut): Sure. Sure. And I just wanna take a second to, clarify. You know, it’s something that kinda comes up often, and I I don’t I don’t think it gets it’s it’s cleared up enough is that so, you know, we have this cloud ID here. So, you know, you can open this from anywhere in the world.

But the virtual PLC run times get installed on computers preferably very locally, you know, on the machine, on the factory floor, something like that. I I’ve got, an edge computer right here. Just as an example. I mean, this is something you would just pop in the control panel and you can install OT on this. So to answer your question better, Shawn, you know, to get to, you know, the remote IO that you need essentially, or actually in the, in the case of this, this has onboard IO.

You know, you’re looking at connecting with MOBAs, PCP, Ethernet IP. I I know that a lot more protocols are coming. Profinet. So how you would do that is that you have that plus sign up here and add a driver config. We’re just gonna do, Modbus real quick.

Henrik Pedersen (OTee): Mhmm.

Jacob Abel (Edgenaut): And we wanna add a TCP client. So you can name the client, tell it how fast to pull, you know, any delays, put in the IP address. Just an example. Do the port number if you need and then add your requests. You know, you have support for, all the main function codes and mod bus right here, you know, read holding, read input, you know, write multiple coils, all that good stuff, you know, tell address how many registers you wanna do, timeouts, slave ID.

And then, you know, once you’ve done that, so let’s say, you know, I’m gonna read, and holding registers here, the table on the right auto updates. You can do aliases for each one of these. You can just do register one Mhmm. As an example

Shawn Tierney (Host): It’s showing just for the audio audience, it’s showing the absolute address for all these modbus, variables and then, has the symbols, and he’s putting in his own symbol name. It has a default symbol name of symbol dash something, and he’s putting his own in, like, register one, which makes it easier. Yeah.

Jacob Abel (Edgenaut): Good point. Yeah. Good point. Thanks, Shawn. So, yeah, once once you put in your request and you can throw in some aliases, for the different registers, you know, you can go back to your program and here’s this, sample variable that I just added from earlier.

You know, you can the registers are 16 bits. I’m gonna select, an int. And what you can do here now is select those modbus requests that you just set up. So it automatically maps these to those variables for you. So that that way you don’t have to do anything anything manual, like have a separate program to say, you know, this tag equals, you know, register 40,001.

You know, it’s already mapped for you. So that’s that’s essentially how you would connect to remote IO is, just add a client in the driver configs and, fill in all your info and be off and running.

Shawn Tierney (Host): That’s excellent. I really liked how you were able to easily map the register to the modbus value you’re reading in or writing to to your, variable so you can use that in your program. That was very easy to do.

Jacob Abel (Edgenaut): Oh, yeah. Yeah. It’s that it’s like I said, that’s one of the things that I love about this interface is that everything is just very straightforward. You know, it’s it’s super easy to just stumble upon whatever it is you need and figure it out.

Henrik Pedersen (OTee): And just just, to add to to kinda your your processors, like, once you have created that connection between the IO and and and the program, you basically just, compile it and download it to the to the runtime again, and and it executes locally the based on the yeah. Nice.

Jacob Abel (Edgenaut): Oh, right. Good point. Yeah. Of of course, after we add something, we do have to redownload. So

Shawn Tierney (Host): Very interesting. Well, that answers my question.

Jacob Abel (Edgenaut): I think that’s that’s about it for the the demo. I mean, unless, Shawn, you have any more questions about the interface here.

Shawn Tierney (Host): No. It looked pretty straightforward to me, Hendrik. I don’t know. Did you have anything else you wanted to discuss while we have the demo up?

Henrik Pedersen (OTee): Nope. Not nothing related to this except for that, you know, this is probably something that’s quite new in the OT space is that this is a software service, meaning that there are continuous development going on and releases, and improvements to the software all the time. Like literally every week we deploy new improvements. And, and what, I typically say is that like, the, you know, if you if you if you sign up with OT, what you what you will experience is that the actual software keeps on becoming better over time and not is not going to become outdated. It’s going to be just better over time.

And I think that’s part of what I really loved about the innovation space, innovation happening around IT is that that, that has become the new de facto standard in how you develop software and great software. And I think we in, in, in the OT space, we need to adopt that same methodology of developing software, something that continuously becomes better over time.

Shawn Tierney (Host): Yeah. And I would just say, you know, if you’re if you’re on the OT side of things, you wanna be in six eleven thirty one dash three languages, because these are things that your staff, you know, what you know, your electricians and technicians and even engineers, you know, should know, should be getting up to speed. I don’t know. We’re at the automation school. We’re teaching, structured text.

And so, easier. I look at this, and I’m like, this is a lot easier than trying to learn c plus or or JavaScript. So in any case, I think, you know, if it’s an OT side real IO control, real control system or data collection, you know, you know, very important, you know, mission critical data collection, then, you know, I’d rather have this than somebody trying to write some custom code for me and, you know, use some kind of computer language who doesn’t understand, you know, the OT side of things. So, I could definitely see the advantage of your system, Henrik.

Henrik Pedersen (OTee): Yep. I I I also wanted to say to that, Stike, the I I do not believe the EIC standards in general will disappear. They exist for a very good reason. Right. Exists to standardise to to ensure safety and determinists, determinism in this.

So I don’t think they will disappear. But there are obviously advances now with AI and things like that that can can help us create these things much faster and much more efficient and things like that. So, so but, but the EIC standards, I think, will be there for a very long time. Obviously, the 06/4099 standard is is really exciting, and and we believe that that can be, yeah, that that can clearly be there, but it’s still a new EIC standard. So,

Shawn Tierney (Host): it’s not think what we’re gonna see is we’re gonna see a lot more libraries fleshed out. There’ll be a lot less writing from scratch. We’ve interviewed on the History of Automation podcast. We’ve interviewed some big integrators, and they’re at a point now, you know, twenty, thirty years on that they have libraries for everything. And I think that’s where we’ll see, you know, much like the DCS, I think, vendors went two years ago.

But I still think that the there’s a reason for these languages. There’s a reason to be able to edit things while they run. There’s a reason for different languages for different applications and different, people maintaining them. So I agree with you on that. I don’t I don’t think we’re we’re gonna see the end of these, these standard languages that have done us very well since the, you know, nineteen seventies.

Jacob Abel (Edgenaut): I just wanna add a bit on there about, Shawn, you mentioned, you know, doing less code. I I did show earlier in the bottom right hand corner here, we have our our little AI assistant, Martha. I don’t believe the feature, it has been released yet. You know, Henrik, correct me if I’m wrong, but I know one of the things that’s coming is, AI code generation, you know, similar to that of cloud or chat GPT. So it’s going to, you know, you can open this guy up here.

You know, right right now, I think it’s just for, help topics, but you’ll be able to talk to Martha and she’s gonna generate code for you in your program there all built in.

Henrik Pedersen (OTee): Yeah. Yeah. That’s that’s coming really fast now. So, it’s it’s not been implemented yet, but it’s, it’s right around the corner.

Shawn Tierney (Host): Yeah. And it’s it’s not gonna be able to it’s you’re not gonna be able to hook a camera up to it and, like, take pictures of your machine and say, okay. Write the control code for this. But, you know, if you had a, you know, process that had 12 steps in it, the AI could definitely help you generate that code and and other code. And we’ll have to have Henrik and Jake back on to talk about that when it comes out, but, you know, it’s gonna be able to save you, reduce the tedious part of the the coding.

You know, if you need an array of so many tags and so many dimensions or, you know, the stuff that, you know, it would just be the typing intensive, it’s gonna be able to help you with that, and then you can actually put the context in there. Just like, you can pull up a template in Word for a letter, and then you can fill in the blanks. You know? And and, of course, AI is helping make that easier too. But, in any case, Henrik, maybe you can come back on when that feature launches.

Henrik Pedersen (OTee): Yeah. Absolutely. And I’m also excited about just a simple a use case of of translating something. Right? Translating your existing let’s say if it’s a proprietary code or something like that, like, getting it getting it standardized and translating it to the ESE six eleven thirty one standard, for instance, or, so so the obviously AI is, like, perfect for this space.

It’s there is no doubt, And and it’s, like, that’s also why I’m so excited about, like, what’s going on at the moment. It’s like there’s so much innovation potential, in the on the OT side now that, they are with all these new technologies.

Shawn Tierney (Host): Yeah. Absolutely. Absolutely. Well, gentlemen, was there anything else you wanted to cover?

Henrik Pedersen (OTee): I think just just one final thing from from me is, like, we thought a lot about it, like, before this this episode, and we thought, like, let’s offer let’s offer the listeners something something of of true value. So so we thought, the, you know, after this after this episode launched, we want to want to offer anyone out there that’s listening a free, completely hands on trial of our technology, in their in their in their environment or on their Raspberry Pi or whatever. So just just reach out to us if you wanna do that. And, and I yeah. We’ll get you set up for for for testing this, and it’s not gonna cost you anything.

Shawn Tierney (Host): Well, that’s great. And, guys, if you’re listening, if you do take advantage of that free trial, please let me know what you thought about it. But, Henrik, thank you so much for, that offer to our listening audience. Guys, don’t be bashful. Reach out to him.

Reach out to Jake. Jake, thank you for doing the demo as well. Really appreciate it. My pleasure. Any final words, Henrik, before we close out?

Henrik Pedersen (OTee): No. It’s been great. Great, being here, Shawn, and thanks for for helping us.

Shawn Tierney (Host): Well, I hope you enjoyed that episode. I wanna thank Hendrik and Jacob for coming on the show, telling us all about OT virtual PLCs, and then giving us a demo. I thought it was really cool. Now if any of you guys take them up on their free trial, please let me know what you think. I’d love to hear from you.

And, with that, I do wanna thank OT for sponsoring this episode so we could release it completely ad free. And I also wanna thank you for tuning back in this week. We have another podcast coming out next week. It’ll be early because I will be traveling and doing an event with a vendor. And so expect that instead of coming out on Wednesday to come out on Monday if all goes as planned.

And then we will be skipping the Thanksgiving, week, and then we’ll be back in the in the, in December, and then we have shows lined up for the new year already as well. So thank you for being a listener, a viewer, and, please, wherever you’re consuming the show, whether it’s on YouTube or on the automation blog or at iTunes or Spotify or Google Podcasts or anywhere, please give us a thumbs up and a like or a five star review because that really helps us expand our audience and find new vendors to come on the show. And with that, I’m gonna end by wishing you good health and happiness. And until next time, my friends, peace.

Until next time, Peace ✌️

If you enjoyed this content, please give it a Like, and consider Sharing a link to it as that is the best way for us to grow our audience, which in turn allows us to produce more content 🙂

Shawn M Tierney

Technology Enthusiast & Content Creator

Support our work and gain access to hundreds members only articles and videos by becoming a member at The Automation Blog or on YouTube. You’ll also find all of my affordable PLC, HMI, and SCADA courses at TheAutomationSchool.com.

Shawn Tierney is a lifelong Technology Enthusiast who began programing in the early 80's on the Apple II and VIC-20 personal computers. After earning a degree in Electronics, he worked as a Certified Controls and Information Automation Specialist for 25 years before launching The Automation Blog and School in 2013.

Latest posts by Shawn Tierney

(see all)(no views)