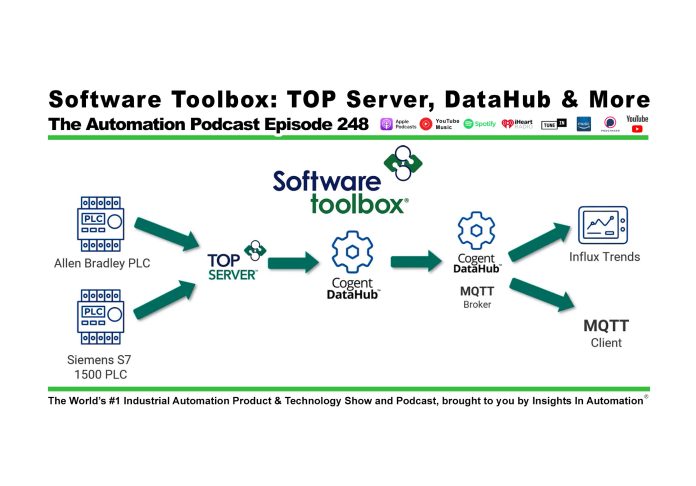

Shawn Tierney meets up with Connor Mason of Software Toolbox to learn their company, products, as well as see a demo of their products in action in this episode of The Automation Podcast.

For any links related to this episode, check out the “Show Notes” located below the video.

Listen to The Automation Podcast from The Automation Blog:

Podcast: Play in new window | Download

The Automation Podcast, Episode 248 Show Notes:

Special thanks to Software Toolbox for sponsoring this episode so we could release it “ad free!” To learn about Software Toolbox please checkout the below links:

Read the transcript on The Automation Blog: (automatically generated)

Shawn Tierney (Host): Welcome back to the automation podcast. My name is Shawn Tierney with Insights and Automation, and I wanna thank you for tuning back in this week. Now this week on the show, I meet up with Connor Mason from Software Toolbox, who gives us an overview of their product suite, and then he gives us a demo at the end. And even if you’re listening, I think you’re gonna find the demo interesting because Connor does a great job of talking through what he’s doing on the screen. With that said, let’s go ahead and jump into this week’s episode with Connor Mason from Software Toolbox.

I wanna welcome Connor from Software Toolbox to the show. Connor, it’s really exciting to have you. It’s just a lot of fun talking to your team as we prepared for this, and, I’m really looking forward to because I just know in your company over the years, you guys have so many great solutions that I really just wanna thank you for coming on the show. And before you jump into talking about products and technologies Yeah. Could you first tell us just a little bit about yourself?

Connor Mason (Guest): Absolutely. Thanks, Shawn, for having us on. Definitely a pleasure to be a part of this environment. So my name is Connor Mason. Again, I’m with Software Toolbox.

We’ve been around for quite a while. So we’ll get into some of that history as well before we get into all the the fun technical things. But, you know, I’ve worked a lot with the variety of OT and IT projects that are ongoing at this point. I’ve come up through our support side. It’s definitely where we grow a lot of our technical skills.

It’s a big portion of our company. We’ll get that into that a little more. Currently a technical application consultant lead. So like I said, I I help run our support team, help with these large solutions based projects and consultations, to find what’s what’s best for you guys out there. There’s a lot of different things that in our in our industry is new, exciting.

It’s fast paced. Definitely keeps me busy. My background was actually in data analytics. I did not come through engineering, did not come through the automation, trainings at all. So this is a whole new world for me about five years ago, and I’ve learned a lot, and I really enjoyed it.

So, I really appreciate your time having us on here,

Shawn Tierney (Host): Shawn. Well, I appreciate you coming on. I’m looking forward to what you’re gonna show us today. I had a the audience should know I had a little preview of what they were gonna show, so I’m looking forward to it.

Connor Mason (Guest): Awesome. Well, let’s jump right into it then. So like I said, we’re here at Software Toolbox, kinda have this ongoing logo and and just word map of connect everything, and that’s really where we lie. Some people have called us data plumbers in the past. It’s all these different connections where you have something, maybe legacy or something new, you need to get into another system.

Well, how do you connect all those different points to it? And, you know, throughout all these projects we worked on, there’s always something unique in those different projects. And we try to work in between those unique areas and in between all these different integrations and be something that people can come to as an expert, have those high level discussions, find something that works for them at a cost effective solution. So outside of just, you know, products that we offer, we also have a lot of just knowledge in the industry, and we wanna share that. You’ll kinda see along here, there are some product names as well that you might recognize.

Our top server and OmniServer, we’ll be talking about LOPA as well. It’s been around in the industry for, you know, decades at this point. And also our symbol factory might be something you you may have heard in other products, that they actually utilize themselves for HMI and and SCADA graphics. That is that is our product. So you may have interacted it with us without even knowing it, and I hope we get to kind of talk more about things that we do.

So before we jump into all the fun technical things as well, I kind of want to talk about just the overall software toolbox experience as we call it. We’re we’re more than just someone that wants to sell you a product. We we really do work with, the idea of solutions. How do we provide you value and solve the problems that you are facing as the person that’s actually working out there on the field, on those operation lines, and making things as well. And that’s really our big priority is providing a high level of knowledge, variety of the things we can work with, and then also the support.

It’s very dear to me coming through the the support team is still working, you know, day to day throughout that software toolbox, and it’s something that has been ingrained into our heritage. Next year will be thirty years of software toolbox in 2026. So we’re established in 1996. Through those thirty years, we have committed to supporting the people that we work with. And I I I can just tell you that that entire motto lives throughout everyone that’s here.

So from that, over 97% of the customers that we interact with through support say they had an awesome or great experience. Having someone that you can call that understands the products you’re working with, understands the environment you’re working in, understands the priority of certain things. If you ever have a plant shut down, we know how stressful that is. Those are things that we work through and help people throughout. So this really is the core pillars of Software Toolbox and who we are, beyond just the products, and and I really think this is something unique that we have continued to grow and stand upon for those thirty years.

So jumping right into some of the industry challenges we’ve been seeing over the past few years. This is also a fun one for me, talking about data analytics and tying these things together. In my prior life and education, I worked with just tons of data, and I never fully knew where it might have come from, why it was such a mess, who structured it that way, but it’s my job to get some insights out of that. And knowing what the data actually was and why it matters is a big part of actually getting value. So if you have dirty data, if you have data that’s just clustered, it’s in silos, it’s very often you’re not gonna get much value out of it.

This was a study that we found in 2024, from Garner Research, And it said that, based on the question that business were asked, were there any top strategic priorities for your data analytics functions in 2024? And almost 50%, it’s right at ’49, said that they wanted to improve data quality, and that was a strategic priority. This is about half the industry is just talking about data quality, and it’s exactly because of those reasons I said in my prior life gave me a headache, to look at all these different things that I don’t even know where they became from or or why they were so different. And the person that made that may have been gone may not have the contacts, and making that from the person that implemented things to the people that are making decisions, is a very big task sometimes. So if we can create a better pipeline of data quality at the beginning, makes those people’s lives a lot easier up front and allows them to get value out of that data a lot quicker.

And that’s what businesses need.

Shawn Tierney (Host): You know, I wanna just data quality. Right? Mhmm. I think a lot of us, when we think of that, we think of, you know, error error detection. We think of lost connections.

We think of, you know, just garbage data coming through. But I I think from an analytical side, there’s a different view on that, you know, in line with what you were just saying. So how do you when you’re talking to somebody about data quality, how do you get them to shift gears and focus in on what you’re talking about and not like a quality connection to the device itself?

Connor Mason (Guest): Absolutely. Yeah. We I kinda live in both those worlds now. You know, I I get to see that that connection state. And when you’re operating in real time, that quality is also very important to you.

Mhmm. And I kind of use that at the same realm. Think of that when you’re thinking in real time, if you know what’s going on in the operation and where things are running, that’s important to you. That’s the quality that you’re looking for. You have to think beyond just real time.

We’re talking about historical data. We’re talking about data that’s been stored for months and years. Think about the quality of that data once it’s made up to that level. Are they gonna understand what was happening around those periods? Are they gonna understand what those tags even are?

Are they gonna understand what those conventions that you’ve implemented, to give them insights into this operation. Is that a clear picture? So, yeah, you’re absolutely right. There are two levels to this, and and that is a big part of it. The the real time data and historical, and we’re gonna get some of that into into our demo as well.

It it’s a it’s a big area for the business, and the people working in the operations.

Shawn Tierney (Host): Yeah. I think quality too. Think, you know, you may have data. It’s good data. It was collected correctly.

You had a good connection to the device. You got it. You got it as often as you want. But that data could really be useless. It could tell you nothing.

Connor Mason (Guest): Right. Exactly.

Shawn Tierney (Host): Right? It could be a flow rate on part of the process that irrelevant to monitoring the actual production of the product or or whatever you’re making. And, you know, I’ve known a lot of people who filled up their databases, their historians, with they just they just logged everything. And it’s like a lot of that data was what I would call low quality because it’s low information value. Right?

Absolutely. I’m sure you run into that too.

Connor Mason (Guest): Yeah. We we run into a lot of people that, you know, I’ve got x amount of data points in my historian and, you know, then we start digging into, well, I wanna do something with it or wanna migrate. Okay. Like, well, what do you wanna achieve at the end of this? Right?

And and asking those questions, you know, it’s great that you have all these things historized. Are you using it? Do you have the right things historized? Are they even set up to be, you know, worked upon once they are historized by someone outside of this this landscape? And I think OT plays such a big role in this, and that’s why we start to see the convergence of the IT and OT teams just because that communication needs to occur sooner.

So we’re not just passing along, you know, low quality data, bad quality data as well. And we’ll get into some of that later on. So to jump into some of our products and solutions, I kinda wanna give this overview of the automation pyramid. This is where we work from things like the field device communications. And you you have certain sensors, meters, actuators along the actual lines, wherever you’re working.

We work across all the industries, so this can vary between those. Through there, you work up kind of your control area. A lot of control engineers are working. This is where I think a lot of the audience is very familiar with PLCs. Your your typical name, Siemens, Rockwell, your Schneiders that are creating, these hardware products.

They’re interacting with things on the operation level, and they’re generating data. That that was kind of our bread and butter for a very long time and still is that communication level of getting data from there, but now getting it up the stack further into the pyramid of your supervisory, MES connections, and it’ll also now open to these ERP. We have a lot of large corporations that have data across variety of different solutions and also want to integrate directly down into their operation levels. There’s a lot of value to doing that, but there’s also a lot of watch outs, and a lot of security concerns. So that’ll be a topic that we’ll be getting into.

We also all know that the cloud is here. It’s been here, and it’s it’s gonna continue to push its way into, these cloud providers into OT as well. There there’s a lot of benefit to it, but there there’s also some watch outs as this kind of realm, changes in the landscape that we’ve been used to. So there’s a lot of times that we wanna get data out there. There’s value into AI agents.

It’s a hot it’s a hot commodity right now. Analytics as well. How do we get those things directly from shop floor, up into the cloud directly, and how do we do that securely? It’s things that we’ve been working on. We’ve had successful projects, continues to be an interest area and I don’t see it slowing down at all.

Now, when we kind of begin this level at the bottom of connectivity, people mostly know us for our top server. This is our platform for industrial device connectivity. It’s a thing that’s talking to all those different PLCs in your plant, whether that’s brownfield or greenfield. We pretty much know that there’s never gonna be a plant that’s a single PLC manufacturer, that exists in one plant. There’s always gonna be something that’s slightly different.

Definitely from Brownfield, things different engineers made different choices, things have been eminent, and you gotta keep running them. TopServe provides this single platform to connect to a long laundry list of different PLCs. And if this sounds very familiar to Kepserver, well, you’re not wrong. Kepserver is the same exact technology that TopServer is. What’s the difference then is probably the biggest question we usually get.

The difference technology wise is nothing. The difference in the back end is that actually it’s all the same product, same product releases, same price, but we have been the biggest single source of Kepserver or Topsyra implementation into the market, for almost two plus decades at this point. So the single biggest purchase that we own this own labeled version of Kepserver to provide to our customers. They interact with our support team, our solutions teams as well, and we sell it along the stack of other things because it it fits so well. And we’ve been doing this since the early two thousands when, Kepware was a a much smaller company than it is now, and we’ve had a really great relationship with them.

So if you’ve enjoyed the technology of of Kepserver, maybe there’s some users out there. If you ever heard of TopServer and that has been unclear, I hope this clear clarifies it. But it it is a great technology stack that that we build upon and we’ll get into some of that in our demo. Now the other question is, what if you don’t have a standard communication protocol, like a modbus, like an Allen Bradley PLC as well? We see this a lot with, you know, testing areas, pharmaceuticals, maybe also in packaging, barcode scanners, weigh scales, printers online as well.

They they may have some form of basic communications that talks over just TCP or or serial. And how do you get that information that’s really valuable still, but it’s not going through a PLC. It’s not going into your typical agent mind SCADA. It might be very manual process for a lot of these test systems as well, how they’re collecting and analyzing the data. Well, you may have heard of our Arm server as well.

It’s been around, like I said, for a couple decades and just a proven solution that without coding, you can go in and build a custom protocol that expects a format from that device, translates it, puts it into standard tags, and now that those tags can be accessible through the open standards of OPC, or to it was a a Veeva user suite link as well. And that really provides a nice combination of your standard communications and also these more custom communications may have been done through scripting in the past. Well, you know, put this onto, an actual server that can communicate through those protocols natively, and just get that data into those SCADA systems, HMIs, where you need it.

Shawn Tierney (Host): You know, I used that. Many years ago, I had an integrator who came to me. He’s like, Shawn, I wanna this is back in the RSVUE days. He’s like, Shawn, I I got, like, 20 Euotherm devices on a four eighty five, and they speak ASCII, and I gotta I gotta get into RSVUE 32. And, you know, OmniSIR, I love that you could you could basically developing and we did Omega and some other devices too.

You’re developing your own protocol, but it’s beautiful. And and the fact that when you’re testing it, it color codes everything. So you know, hey. That part worked. The header worked.

The data worked. Oh, the trailing didn’t work, or the terminated didn’t work, or the data’s not in the right format. Or I just it was a joy to work with back then, and I can imagine it’s only gotten better since.

Connor Mason (Guest): Yeah. I think it’s like a little engineer playground where you get in there. It started really decoding and seeing how these devices communicate. And then once you’ve got it running, it it’s one of those things that it it just performs and, is saved by many people from developing custom code, having to manage that custom code and integrations, you know, for for many years. So it it’s one of those things that’s kinda tried, tested, and, it it’s kind of a staple still our our base level communications.

Alright. So moving along kind of our automation pyramid as well. Another part of our large offering is the Cogent data hub. Some people may have heard from this as well. It’s been around for a good while.

It’s been part of our portfolio for for a while as well. This starts building upon where we had the communication now up to those higher echelons of the pyramid. This is gonna bring in a lot of different connectivities. You if you’re not if you’re listening, it it’s kind of this cog and spoke type of concept for real time data. We also have historical implementations.

You can connect through a variety of different things. OPC, both the profiles for alarms and events, and even OPC UA’s alarming conditions, which is still getting adoption across the, across the industry, but it is growing. As part of the OPC UA standard, we have integrations to MQTT. It can be its own MQTT broker, and it can also be an MQTT client. That has grown a lot.

It’s one of those things that lives be besides OPC UA, not exactly a replacement. If you ever have any questions about that, it’s definitely a topic I love to talk about. There’s space for for this to combine the benefits of both of these, and it’s so versatile and flexible for these different type of implementations. On top of that, it it’s it’s a really strong tool for conversion and aggregation. You kind of add this, like, its name says, it’s a it’s a data hub.

You send all the different information to this. It stores it into, a hierarchy with a variety of different modeling that you can do within it. That’s gonna store these values across a standard data format. Once I had data into this, any of those different connections, I can then send data back out. So if I have anything that I know is coming in through a certain plug in like OPC, bring that in, send it out to on these other ones, OPC, DA over to MQTT.

It could even do DDA if I’m still using that, which I probably wouldn’t suggest. But overall, there’s a lot of good benefits from having something that can also be a standardization, between all your different connections. I have a lot of different things, maybe variety of OPC servers, legacy or newer. Bring that into a data hub, and then all your other connections, your historians, your MAS, your SCADAs, it can connect to that single point. So it’s all getting the same data model and values from a single source rather than going out and making many to many connections.

A a large thing that it was originally, used for was getting around DCOM. That word is, you know, it might send some shivers down people’s spines still, to this day, but it’s it’s not a fun thing to deal with DCOM and also with the security hardening. It’s just not something that you really want to do. I’m sure there’s a lot of security professionals would advise against EPRA doing it. This tunneling will allow you to have a data hub that locally talks to any of the DA server client, communicate between two data hubs over a tunnel that pushes the data just over TCP, takes away all the comm wrappers, and now you just have values that get streamed in between.

Now you don’t have to configure any DCOM at all, and it’s all local. So a lot of people went transitioning, between products where maybe the server only supports OPC DA, and then the client is now supporting OPC UA. They can’t change it yet. This has allowed them to implement a solution quickly and cost and at a cost effective price, without ripping everything out.

Shawn Tierney (Host): You know, I wanna ask you too. I can see because this thing is it’s a data hub. So if you’re watching and you’re if you’re listening and not watching, you you’re not gonna see, you know, server, client, UAD, a broker, server, client. You know, just all these different things up here on the site. Do you what how does somebody find out if it does what they need?

I mean, do you guys have a line they can call to say, I wanna do this to this. Is that something Data Hub can do, or is there a demo? What would you recommend to somebody?

Connor Mason (Guest): Absolutely. Reach out to us. We we have a a lot of content outline, and it’s not behind any paywall or sign in links even. You you can always go to our website. It’s just softwaretoolbox.com.

Mhmm. And that’s gonna get you to our product pages. You can download any product directly from there. They have demo timers. So typically with, with coaching data hub, after an hour, it will stop.

You can just rerun it. And then call our team. Yeah. We have a solutions team that can work with you on, hey. What do I need as well?

Then our support team, if you run into any issues, can help you troubleshoot that as well. So, I’ll have some contact information at the end, that’ll get some people to, you know, where they need to go. But you’re absolutely right, Shawn. Because this is so versatile, everyone’s use case of it is usually something a little bit different. And the best people to come talk to that is us because we’ve we’ve seen all those differences.

So

Shawn Tierney (Host): I think a lot of people run into the fact, like, they have a problem. Maybe it’s the one you said where they have the OPC UA and it needs to connect to an OPC DA client. And, you know, and a lot of times, they’re they’re a little gunshot to buy a license because they wanna make sure it’s gonna do exactly what they need first. And I think that’s where having your people can, you know, answer their questions saying, yes. We can do that or, no.

We can’t do that. Or, you know, a a demo that they could download and run for an hour at a time to actually do a proof of concept for the boss who’s gonna sign off on purchasing this. And then the other thing is too, a lot of products like this have options. And you wanna make sure you’re buying the ticking the right boxes when you buy your license because you don’t wanna buy something you’re not gonna use. You wanna buy the exact pieces you need.

So I highly recommend I mean, this product just does like, I have, in my mind, like, five things I wanna ask right now, but not gonna. But, yeah, def definitely, when it when it comes to a product like this, great to touch base with these folks. They’re super friendly and helpful, and, they’ll they’ll put you in the right direction.

Connor Mason (Guest): Yeah. I I can tell you that’s working someone to support. Selling someone a solution that doesn’t work is not something I’ve been doing. Bad day. Right.

Exactly. Yeah. And we work very closely, between anyone that’s looking at products. You know, me being as technical product managers, well, I I’m engaged in those conversations. And Mhmm.

Yeah. If you need a demo license, reach out to us to extend that. We wanna make sure that you are buying something that provides you value. Now kind of moving on into a similar realm. This is one of our still somewhat newer offerings, I say, but we’ve been around five five plus years, and it’s really grown.

And I kinda said here, it’s called OPC router, and and it’s not it’s not a networking tool. A lot of people may may kinda get that. It’s more of a, kind of a term about, again, all these different type of connections. How do you route them to different ways? It it kind of it it separates itself from the Cogent data hub, and and acting at this base level of being like a visual workflow that you can assign various tasks to.

So if I have certain events that occur, I may wanna do some processing on that before I just send data along, where the data hub is really working in between converting, streaming data, real time connections. This gives you a a kind of a playground to work around of if I have certain tasks that are occurring, maybe through a database that I wanna trigger off of a certain value, based on my SCADA system, well, you can build that in in these different workflows to execute exactly what you need. Very, very flexible. Again, it has all these different type of connections. The very unique ones that have also grown into kind of that OT IT convergence, is it can be a REST API server and client as well.

So I can be sending out requests to, RESTful servers where we’re seeing that hosted in a lot of new applications. I wanna get data out of them. Or once I have consumed a variety of data, I can become the REST server in OPC router and offer that to other applications to request data from itself. So, again, it can kind of be that centralized area of information. The other thing as we talked about in the automation pyramid is it has connections directly into SAP and ERP systems.

So if you have work orders, if you have materials, that you wanna continue to track and maybe trigger things based off information from your your operation floors via PLCs tracking, how they’re using things along the line, and that needs to match up with what the SAP system has for, the amount of materials you have. This can be that bridge. It’s really is built off the mindset of the OT world as well. So we kinda say this helps empower the OT level because we’re now giving them the tools to that they understand what what’s occurring in their operations. And what could you do by having a tool like this to allow you to kind of create automated workflows based off certain values and certain events and automate some of these things that you may be doing manually or doing very convoluted through a variety of solutions.

So this is one of those prod, products as well that’s very advanced in the things that supports. Linux and Docker containers is, is definitely could be a hot topic, rightly fleet rightfully so. And this can run on a on a Docker container deployed as well. So we we’ve seen that with the I IT folks that really enjoy being able to control and to higher deployment, allows you to update easily, allows you to control and spin up new containers as well. This gives you a lot of flexibility to to deploy and manage these systems.

Shawn Tierney (Host): You know, I may wanna have you back on to talk about this. I used to there’s an old product called Rascal that I used to use. It was a transaction manager, and it would based on data changing or on a time that as a trigger, it could take data either from the PLC to the database or from the database to the PLC, and it would work with stored procedures. And and this seems like it hits all those points, And it sounds like it’s a visual like you said, right there on the slide, visual workflow builder.

Connor Mason (Guest): Yep.

Shawn Tierney (Host): So you really piqued my interest with this one, and and it may be something we wanna come back to and and revisit in the future, because, it just it’s just I know that that older product was very useful and, you know, it really solved a lot of old applications back in the day.

Connor Mason (Guest): Yeah. Absolutely. And this this just takes that on and builds even more. If you if anyone was, kind of listening at the beginning of this year or two, a conference called Prove It that was very big in the industry, we were there to and we presented on stage a solution that we had. Highly recommend going searching for that.

It’s on our web pages. It’s also on their YouTube links, and it’s it’s called Prove It. And OPC router was a big part of that in the back end. I would love to dive in and show you the really unique things. Kind of as a quick overview, we’re able to use Google AI vision to take camera data and detect if someone was wearing a hard hat.

All that logic and behind of getting that information to Google AI vision, was through REST with OPC router. Then we were parsing that information back through that, connection and then providing it back to the PLCs. So we go all the way from a camera to a PLC controlling a light stack, up to Google AI vision through OPC router, all on hotel Wi Fi. It’s very imp it’s very, very fun presentation, and, our I think our team did a really great job. So a a a pretty new offering I have I wanna highlight, is our is our data caster.

This is a an actual piece of hardware. You know, our software toolbox is we we do have some hardware as well. It’s just, part of the nature of this environment of how we mesh in between things. But the the idea is that, there’s a lot of different use cases for HMI and SCADA. They have grown so much from what they used to be, and they’re very core part of the automation stack.

Now a lot of times, these are doing so many things beyond that as well. What we found is that in different areas of operations, you may not need all that different control. You may not even have the space to make up a whole workstation for that as well. What this does, the data caster, is, just simply plug it plugs it into any network and into an HDMI compatible display, and it gives you a very easy configure workplace to put a few key metrics onto a screen. So if I have different things from you can connect directly to PLCs like Allen Bradley.

You can connect to SQL databases. You can also connect to rest APIs to gather the data from these different sources and build a a a kind of easy to to view, KPI dashboard in a way. So if you’re on a operation line and you wanna look at your current run rate, maybe you have certain things in the POC tags, you know, flow and pressure that’s very important for those operators to see. They may not be, even the capacity to be interacting with anything. They just need visualizations of what’s going on.

This product can just be installed, you know, industrial areas with, with any type of display that you can easily access and and give them something that they can easily look at. It’s configured all through a web browser to display what you want. You can put on different colors based on levels of values as well. And it’s just I feel like a very simple thing that sometimes it seems so simple, but those might be the things that provide value on the actual operation floor. This is, for anyone that’s watching, kind of a quick view of a very simple screen.

What we’re showing here is what it would look like from all the different data sources. So talking directly to ControlLogs PLC, talking to SQL databases, micro eight eight hundreds, an arrest client, and and what’s coming very soon, definitely by the end of this year, is OPC UA support. So any OPC UA server that’s out there that’s already having your PLC data or etcetera, this could also connect to that and get values from there.

Shawn Tierney (Host): Can I can you make it I’m I’m here I go? Can you make it so it, like, changes, like, pages every few seconds?

Connor Mason (Guest): Right now, it is a single page, but this is, like I said, very new product, so we’re taking any feedback. If, yeah, if there’s this type of slideshow cycle that would be, you know, valuable to anyone out there, let us know. We’re definitely always interested to see the people that are actually working out at these operation sites, what what’s valuable to them. Yeah.

Shawn Tierney (Host): A lot of kiosks you see when when you’re traveling, it’ll say, like, line one well, I’ll just throw out there. Line one, and that’ll be on there for five seconds, and then it’ll go line two. That’ll be on there for five seconds, and then line you know, I and that’s why I just mentioned that because I can see that being a question that, that that I would get from somebody who is asking me about it.

Connor Mason (Guest): Oh, great question. Appreciate it. Alright. So now we’re gonna set time for a little hands on demo. For anyone that’s just listening, we’re gonna I’m gonna talk about this at at a high level and walk through everything.

But the idea is that, we have a few different POCs, very common in Allen Bradley and just a a Siemens seven, s seven fifteen hundred that’s in our office, pretty close to me on the other side of the wall wall, actually. We’re gonna first start by connecting that to our top server like we talked about. This is our industrial communication server, that offers both OCDA, OC UA, SweetLink connectivity as well. And then we’re gonna bring this into our Cogent data hub. This we talked about is getting those values up to these higher levels.

What we’ll be doing is also tunneling the data. We talked about being able to share data through the data hubs themselves. Kinda explain why we’re doing that here and the value you can add. And then we’re also gonna showcase adding on MQTT to this level. Taking beta now just from these two PLCs that are sitting on a rack, and I can automatically make all that information available in the MQTT broker.

So any MQTT client that’s out there that wants to subscribe to that data, now has that accessible. And I’ve created this all through a a really simple workflow. We also have some databases connected. Influx, we install with Code and DataHub, has a free visualization tool that kinda just helps you see what’s going on in your processes. I wanna showcase a little bit of that as well.

Alright. So now jumping into our demo, when we first start off here is the our top server. Like I mentioned before, if anyone has worked with KEP server in the past, this is gonna look very similar. Like it because it is. The same technology and all the things here.

The the first things that I wanted to establish in our demo, was our connection to our POCs. I have a few here. We’re only gonna use the Allen Bradley and the Siemens, for the the time that we have on our demo here. But how this builds out as a platform is you create these different channels and the devices connections between them. This is gonna be your your physical connections to them.

It’s either, IP TCPIP connection or maybe your serial connection as well. We have support for all of them. It really is a long list. Anyone watching out there, you can kind of see all the different drivers that that we offer. So allowing this into a single platform, you can have all your connectivity based here.

All those different connections that you now have that up the stack, your SCADA, your historians, MAS even as well, they can all go to a single source. Makes that management, troubleshooting, all those a bit easier as well. So one of the first things I did here, I have this built out, but I’ll kinda walk through what you would typically do. You have your Allen Bradley ControlLogix Ethernet driver here first. You know, I have some IPs in here I won’t show, but, regardless, we have our our our drivers here, and then we have a set of tags.

These are all the global tags in the programming of the PLC. How I got these to to kind of map automatically is in our in our driver, we’re able to create tags automatically. So you’re able to send a command to that device and ask for its entire tag database. They can come back, provide all that, map it out for you, create those tags as well. This saves a lot of time from, you know, an engineer have to go in and, addressing all the individual items themselves.

So once it’s defined in the program project, you’re able to bring this all in automatically. I’ll show now how easy that makes it connecting to something like the Cogent data hub. In a very similar fashion, we have a connection over here to the Siemens, PLC that I also have. You can see beneath it all these different tag structures, and this was created the exact same way. While those those PLC support it, you can do an automatic tag generation, bring in all the structure that you’ve already built out your PLC programming, and and make this available on this OPC server now as well.

So that’s really the basis. We first need to establish communications to these PLCs, get that tag data, and now what do we wanna do with it? So in this demo, what I wanted to bring up was, the code in DataHub next. So here, I see a very similar kind of layout. We have a different set set of plugins on the left side.

So for anyone listening, the Cogent Data Hub again is kind of our aggregation and conversion tool. All these different type of protocols like OPC UA, OPC DA, and OPC A and E for alarms and events. We also support OPC alarms and conditions, which is the newer profile for alarms in OPC UA. We have all a variety of different ways that you can get data out of things and data’s into the data hub. We can also do bridging.

This concept is, how you share data in between different points. So let’s say I had a connection to one OPC server, and it was communicating to a certain PLC, and there were certain registers I was getting data from. Well, now I also wanna connect to a different OPC server that has, entirely different brand of PLCs. And then maybe I wanna share data in between them directly. Well, with this software, I can just bridge those points between them.

Once they’re in the data hub, I can do kind of whatever I want with them. I can then allow them to write between those PLCs and share data that way, and you’re not now having to do any type of hardwiring directly in between them, and then I’m compatible to communicate to each other. Through the standards of OPC and these variety of different communication levels, I can integrate them together.

Shawn Tierney (Host): You know, you bring up a good point. When you do something like that, is there any heartbeat? Like, is there on the general or under under, one of these, topics? Is there are there tags we can use that are from DataHub itself that can be sent to the destination, like a heartbeat or, you know, the merge transactions? Or

Connor Mason (Guest): Yeah. Absolutely. So with this as well, there’s pretty strong scripting engine, and I have done that in the past where you can make internal tags. And that that could be a a timer. It could be a counter.

And and just kind of allows you to create your own tags as well that you could do the same thing, could share that, through bridge connection to a PLC. So, yeah, there there are definitely some people that had those cert and, you know, use cases where they wanna get something to just track, on this software side and get it out to those hardware PLCs. Absolutely.

Shawn Tierney (Host): I mean, when you send out the data out of the PLC, the PLC doesn’t care to take my data. But when you’re getting data into the PLC, you wanna make sure it’s updating and it’s fresh. And so, you know, they throw a counter in there, the script thing, and be able to have that. As as long as you see that incrementing, you know, you got good data coming in. That’s that’s a good feature.

Connor Mason (Guest): Absolutely. You know, another big one is the the redundancy. So what this does is beyond just the OPC, we can make redundancy to basically anything that has two things running of it. So any of these different connections. How it’s unique is what it does is it just looks at the buckets of data that you create.

So for an example, if I do have two different OPC servers and I put them into two areas of, let’s say, OPC server one and OPC server two, I can what now create an OPC redundancy data bucket. And now any client that connects externally to that and wants that data, it’s gonna go talk to that bucket of data. And that bucket of data is going to automatically change in between sources as things go down, things come back up, and the client would never know what’s hap what that happened unless you wanted to. There are internal tasks to show what’s the current source and things, but the idea is to make this trans kind of hidden that regardless of what’s going on in the operations, if I have this set up, I can have my external applications just reading from a single source without knowing that there’s two things behind it that are actually controlling that. Very important for, you know, historian connections where you wanna have a full complete picture of that data that’s coming in.

If you’re able to make a redundant connection to two different, servers and then allow that historian to talk to a single point where it doesn’t have to control that switching back and forth. It it will just see that data flow streamlessly as as either one is up at that time. Kinda beyond that as well, there’s quite a few other different things in here. I don’t think we have time to cover all of them. But for for our demo, what I wanna focus on first is our OPC UA connection.

This allows us both to act as a OPC UA client to get data from any servers out there, like our top server. And also we can act as an OPC UA server itself. So if anything’s coming in from maybe you have multiple connections to different servers, multiple connections to other things that aren’t OPC as well, I can now provide all this data automatically in my own namespace to allow things to connect to me as well. And that’s part of that aggregation feature, and kind of topic I was mentioning before. So with that, I have a connection here.

It’s pulling data all from my top server. I have a few different tags from my Alec Bradley and and my Siemens PLC selected. The next part of this, while I was meshing, was the tunneling. Like I said, this is very popular to get around DCOM issues, but there’s a lot of reasons why you still may use this beyond just the headache of DCOM and what it was. What this runs on is a a TCP stream that takes all the data points as a value, a quality, and a timestamp, and it can mirror those in between another DataHub instance.

So if I wanna get things across a network, like my OT side, where NASH previously, I would have to come in and allow a, open port onto my network for any OPC UA clients, across the network to access that, I can now actually change the direction of this and allow me to tunnel data out of my network without opening up any ports. This is really big for security. If anyone out there, security professional or working as an engineer, you have to work with your IT and security a lot, they don’t you don’t wanna have an open port, especially to your operations and OT side. So this allows you to change that direction of flow and push data out of this direction into another area like a DMZ computer or up to a business level computer as well. The other things as well that I have configured in this demo, the benefit of having that tunneling streaming data across this connection is I can also store this data locally in a, influx database.

The purpose of that then is that I can actually historize this, provide then if this connection ever goes down to backfill any information that was lost during that tunnel connection going down. So with this added layer on and real time data scenarios like OPC UA, unless you have historical access, you would lose a lot of data if that connection ever went down. But with this, I can actually use the back end of this InfluxDB, buffer any values. When my connection comes back up, pass them along that stream again. And if I have anything that’s historically connected, like, another InfluxDB, maybe a PI historian, Vue historian, any historian offering out there that can allow that connection.

I can then provide all those records that were originally missed and backfill that into those systems. So I switched over to a second machine. It’s gonna look very similar here as well. This also has an instance of the Cogent Data Hub running here. For anyone not watching, what we’ve actually have on this side is the the portion of the tunneler that’s sitting here and listening for any data requests coming in.

So on my first machine, I was able to connect my PLCs, gather that information into Cogent DataHub, and now I’m pushing that information, across the network into a separate machine that’s sitting here and listening to gather information. So what I can quickly do is just make sure I have all my data here. So I have these different points, both from my Allen Bradley PLCs. I have a few, different simulation demo points, like temperature, pressure, tank level, a few statuses, and all this is updating directly through that stream as the PLC is updating it as well. I also have my scenes controller.

I have some, current values and a few different counters tags as well. All of this again is being directly streamed through that tunnel. I’m not connecting to an OPC server at all on this side. I can show you that here. There’s no connections configured.

I’m not talking to the PLCs directly on this machine as well. But maybe we’ll pass all the information through without opening up any ports on my OT demo machine per se. So what’s the benefit of that? Well, again, security. Also, the ability to do the store and forward mechanisms.

On the other side, I was logging directly to a InfluxDB. This could be my d- my buffer, and then I was able to configure it where if any values were lost, to store that across the network. So now with this side, if I pull up Chronic Graph, which is a free visualization tool that installs with the DataHub as well, I can see some very nice, visual workflows and and visual diagrams of what is going on with this data. So I have a pressure that is just a simulator in this, Allen Bradley PLC that ramps up and and comes back down. It’s not actually connected to anything that’s reading a real pressure, but you can see over time, I can kind of change through these different layers of time.

And I might go back a little far, but I have a lot of data that’s been stored in here. For a while during my test, I turned this off and, made it fail, but then I came back in and I was able to recreate all the data and backfill it as well. So through through these views, I can see that as data disconnects, as it comes back on, I have a very cyclical view of the data because it was able to recover and store and forward from that source. Like I said, Shawn, data quality is a big thing in this industry. It’s a big thing for people both at the operations side, and both people making decision in the business layer.

So being able to have a full picture, without gaps, it is definitely something that, you should be prioritizing, when you can.

Shawn Tierney (Host): Now what we’re seeing here is you’re using InfluxDB on this, destination PC or IT side PC and chronograph, which was that utility or that package that comes, gets installed. It’s free. But you don’t actually have to use that. You could have sent this in to an OSI pi or Exactly. Somebody else’s historian.

Right? Can you name some of the historians you work with? I know OSI pie.

Connor Mason (Guest): Yeah. Yeah. Absolutely. So there’s quite a few different ones. As far as what we support in the Data Hub natively, Amazon Kinesis, the cloud hosted historian that we can also do the same things from here as well.

Aviva Historian, Aviva Insight, Apache Kafka. This is a a kind of a a newer one as well that used to be a very IT oriented solution, now getting into OT. It’s kind of a similar database structure where things are stored in different topics that we can stream to. On top of that, just regular old ODBC connections. That opens up a lot of different ways you can do it, or even, the old classic OPC, HDA.

So if you have any, historians that that can act as an OPC HDA, connection, we we can also stream it through there.

Shawn Tierney (Host): Excellent. That’s a great list.

Connor Mason (Guest): The other thing I wanna show while we still have some time here is that MQTT component. This is really growing and, it’s gonna continue to be a part of the industrial automation technology stack and conversations moving forward, for streaming data, you know, from devices, edge devices, up into different layers, both now into the OT, and then maybe out to, IT, in our business levels as well, and definitely into the cloud as we’re seeing a lot of growth into it. Like I mentioned with Data Hub, the big benefit is I have all these different connections. I can consume all this data. Well, I can also act as an MQTT broker.

And what what a broker typically does in MQTT is just route data and share data. It’s kind of that central point where things come to it to either say, hey. I’m giving you some new values. Share it with someone else. Or, hey.

I need these values. Can you give me that? It really fits in super well with what this product is at its core. So all I have to do here is just enable it. What that now allows is I have an example, MQTT Explorer.

If anyone has worked with MQTT, you’re probably familiar with this. There’s nothing else I configured beyond just enabling the broker. And you can see within this structure, I have all the same data that was in my Data Hub already. The same things I were collecting from my PLCs and top server. Now I’ve embedded these as MPPT points and now I have them in JSON format with the value, their timestamp.

You can even see, like, a little trend here kind of matching what we saw in Influx. And and now this enables all those different cloud connectors that wanna speak this language to do it seamlessly.

Shawn Tierney (Host): So you didn’t have to set up the PLCs a second time to do this? Nope.

Connor Mason (Guest): Not at all.

Shawn Tierney (Host): You just enabled this, and now the data’s going this way as well. Exactly.

Connor Mason (Guest): Yeah. That’s a really strong point of the Cogent Data Hub is once you have everything into its structure and model, you just enable it to use any of these different connections. You can get really, really creative with these different things. Like we talked about with the the bridging aspect and getting into different systems, even writing down the PLCs. You can make crust, custom notifications and email alerts, based on any of these values.

You could even take something like this MTT connection, tunnel it across to another data hub as well, maybe then convert it to OPC DA. And now you’ve made a a a new connection over to something that’s very legacy as well.

Shawn Tierney (Host): Yeah. That, I mean, the options here are just pretty amazing, all the different things that can be done.

Connor Mason (Guest): Absolutely. Well, I, you know, I wanna jump back into some of our presentation here while we still got the time. And now after we’re kinda done with our demo, there’s so many different ways that you can use these different tools. This is just a really simple, kind of view of the, something that used to be very simple, just connecting OpenSea servers to a variety of different connections, kind of expanding onto with that that’s store and forward, the local influx usage, getting out to things like MTT as well. But there’s a lot more you can do with these solutions.

So like Shawn said, reach out to us. We’re happy to engage and see what we can help you with. I have a few other things before we wrap up. Just overall, it we’ve worked across nearly every industry. We have installations across the globe on all continents.

And like I said, we’ve been around for pushing thirty years next year. So we’ve seen a lot of different things, and we really wanna talk to anyone out there that maybe has some struggles that are going on with just connectivity, or you have any ongoing projects. If you work in these different industries or if there’s nothing marked here and you have anything going on that you need help with, we’re very happy to sit down and let you know if there’s there’s something we can do there.

Shawn Tierney (Host): Yeah. For those who are, listening, I mean, we see most of the big energy and consumer product, companies on that slide. So I’m not gonna read them off, but, it’s just a lot of car manufacturers. You know, these are these are these, the household name brands that everybody knows and loves.

Connor Mason (Guest): So kind of wrap some things up here. We talked about all the different ways that we’ve kind of helped solve things in the past, but I wanna highlight some of the unique ones, that we’ve also gone do some, case studies on and and success stories. So this one I actually got to work on, within the last few years that, a plastic packaging, manufacturer was looking to track uptime and downtime across multiple different lines, and they had a new cloud solution that they were already evaluating. They’re really excited to get into play. They they had a lot of upside to, getting things connected to this and start using it.

Well, what they had was a lot of different PLCs, a lot of different brands, different areas, different, you know, areas of operation that they need to connect to. So what they used was to first get that into our top server, kind of similar to how they showed them use in their in our demo. We just need to get all the data into a centralized platform first, get that data accessible. Then from there, once they had all that information into a centralized area, they used the Cogent Data Hub as well to help aggregate that information and transform it to be sent to the cloud through MQTT. So very similar to the demo here, this is actually a real use case of that.

Getting information from PLCs, structuring it into that how that cloud system needed it for MQTT, and streamlining that data connection to now where it’s just running in operation. They constantly have updates about where their lines are in operation, tracking their downtime, tracking their uptime as well, and then being able to do some predictive analytics in that cloud solution based on their history. So this really enabled them to kind of build from what they had existing. It was doing a lot of manual tracking, into an entirely automated system with management able to see real views of what’s going on at this operation level. Another one I wanna talk about was we we were able to do this success story with, Ace Automation.

They worked with a pharmaceutical company. Ace Automation is a SI and they were brought in and doing a lot of work with some some old DDE connections, doing some custom Excel macros, and we’re just having a hard time maintaining some legacy systems that were just a pain to deal with. They were working with these older files, from some old InTouch histor HMIs, and what they needed to do was get something that was not just based on Excel and doing custom macros. So one product we didn’t get to talk about yet, but we also carry is our LGH file inspector. It’s able to take these files, put them out into a standardized format like CSV, and also do a lot of that automation of when when should these files be queried?

Should they be, queried for different lengths? Should they be output to different areas? Can I set these up in a scheduled task so it can be done automatically rather than someone having to sit down and do it manually in Excel? So they will able to, recover over fifty hours of engineering time with the solution from having to do late night calls to troubleshoot a, Excel macro that stopped working, from crashing machines, because they were running a legacy systems to still support some of the DDE servers, into saving them, you know, almost two hundred plus hours of productivity. Another example, if we’re able to work with a renewable, energy customer that’s doing a lot of innovative things across North America, They had a very ambitious plan to double their footprint in the next two years.

And with that, they had to really look back at their assets and see where they currently stand, how do we make new standards to support us growing into what we want to be. So with this, they had a lot of different data sources currently. They’re all kind of siloed at the specific areas. Nothing was really connected commonly to a corporate level area of historization, or control and security. So again, they they were able to use our top server and put out a standard connectivity platform, bring in the DataHub as an aggregation tool.

So each of these sites would have a top server that was individually collecting data from different devices, and then that was able to send it into a single DataHub. So now their corporate level had an entire view of all the information from these different plants in one single application. That then enabled them to connect their historian applications to that data hub and have a perfect view and make visualizations off of their entire operations. What this allowed them to do was grow without replacing everything. And that’s a big thing that we try to strive on is replacing and ripping out all your existing technologies.

It’s not something you can do overnight. But how do we provide value and gain efficiency with what’s in place and providing newer technologies on top of that without disrupting the actual operation as well? So this was really, really successful. And at the end, I just wanna kind of provide some other contacts and information people can learn more. We have a blog that goes out every week on Thursdays.

A lot of good technical content out there. A lot of recast of the the awesome things we get to do here, the success stories as well, and you can always find that at justblog.softwaretoolbox.com. And again, our main website is justsoftwaretoolbox.com. You can get product information, downloads, reach out to anyone on our team. Let’s discuss what what issues you have going on, any new projects, we’ll be happy to listen.

Shawn Tierney (Host): Well, Connor, I wanna thank you very much for coming on the show and bringing us up to speed on not only software toolbox, but also to, you know, bring us up to speed on top server and doing that demo with top server and data hub. Really appreciate that. And, I think, you know, like you just said, if anybody, has any projects that you think these solutions may be able to solve, please give them a give them a call. And if you’ve already done something with them, leave a comment. You know?

To leave a comment, no matter where you’re watching or listening to this, let us know what you did. What did you use? Like me, I used OmniServer all those many years ago, and, of course, Top Server as an OPC server. But if you guys have already used Software Toolbox and, of course, Symbol Factory, I use that all the time. But if you guys are using it, let us know in the comments.

It’s always great to hear from people out there. I know, you know, with thousands of you guys listening every week, but I’d love to hear, you know, are you using these products? Or if you have questions, I’ll funnel them over to Connor if you put them in the comments. So with that, Connor, did you have anything else you wanted to cover before we close out today’s show?

Connor Mason (Guest): I think that was it, Shawn. Thanks again for having us on. It was really fun.

Shawn Tierney (Host): I hope you enjoyed that episode, and I wanna thank Connor for taking time out of his busy schedule to come on the show and bring us up to speed on software toolbox and their suite of products. Really appreciated that demo at the end too, so we actually got a look at if you’re watching. Gotta look at their products and how they work. And, just really appreciate them taking all of my questions. I also appreciate the fact that Software Toolbox sponsored this episode, meaning we were able to release it to you without any ads.

So I really appreciate them. If you’re doing any business with Software Toolbox, please thank them for sponsoring this episode. And with that, I just wanna wish you all good health and happiness. And until next time, my friends, peace.

Until next time, Peace ✌️

If you enjoyed this content, please give it a Like, and consider Sharing a link to it as that is the best way for us to grow our audience, which in turn allows us to produce more content 🙂

Shawn M Tierney

Technology Enthusiast & Content Creator

Support our work and gain access to hundreds members only articles and videos by becoming a member at The Automation Blog or on YouTube. You’ll also find all of my affordable PLC, HMI, and SCADA courses at TheAutomationSchool.com.

Shawn Tierney is a lifelong Technology Enthusiast who began programing in the early 80's on the Apple II and VIC-20 personal computers. After earning a degree in Electronics, he worked as a Certified Controls and Information Automation Specialist for 25 years before launching The Automation Blog and School in 2013.

Latest posts by Shawn Tierney

(see all)(no views)