In Today’s article I’ll walk you through how you can bring Allen-Bradley Programmable Controller Data into Microsoft Excel 2016 using RSLinx Classic.

NOTE: The below procedure works with any licensed copy of RSLinx Classic, including Single Node, OEM, and Gateway shown below. However, it will not work with the free “Lite” version.

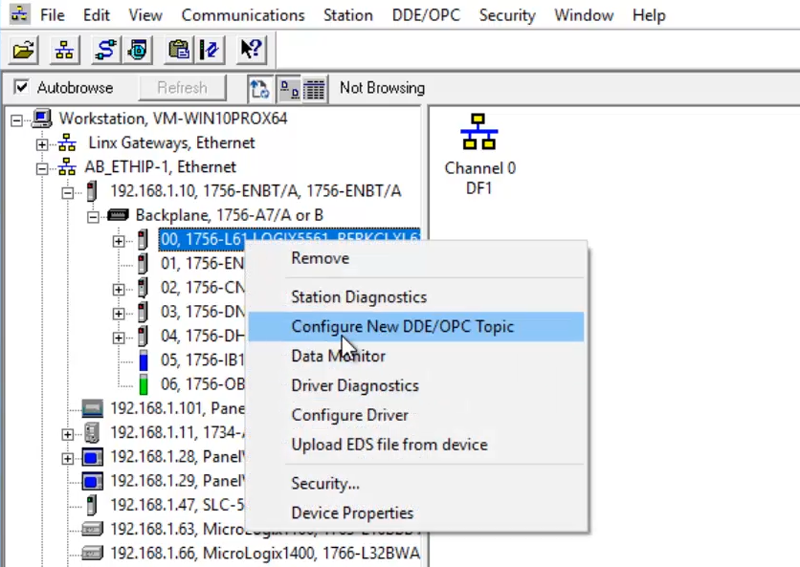

Step 1) Locate the Programmable Controller you’d like to get data from in the RSLinx Classic RSWho window, then right click on it and choose, “Configure New DDE/OPC Topic” as shown below:

Step 1) Locate the Programmable Controller you’d like to get data from in the RSLinx Classic RSWho window, then right click on it and choose, “Configure New DDE/OPC Topic” as shown below:

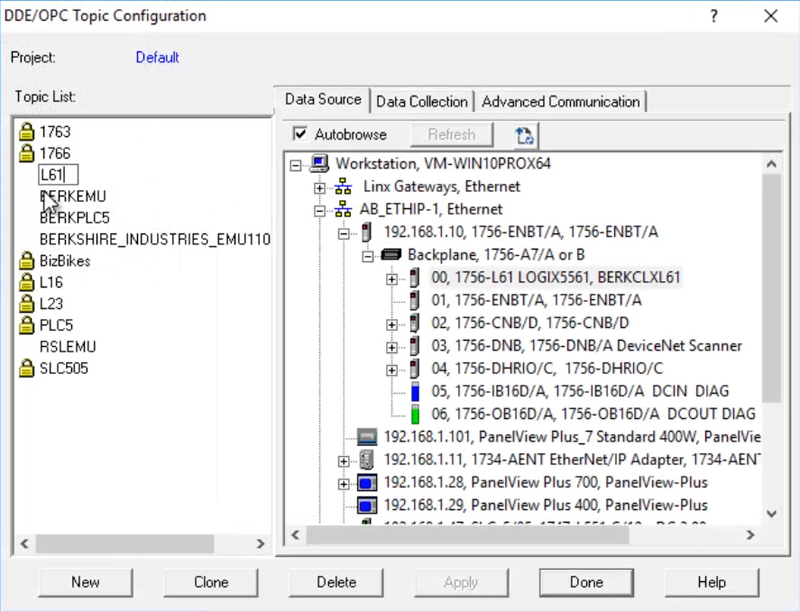

Step 2) Now give your Topic a name. In this example I name my new topic “L61”:

Step 2) Now give your Topic a name. In this example I name my new topic “L61”:

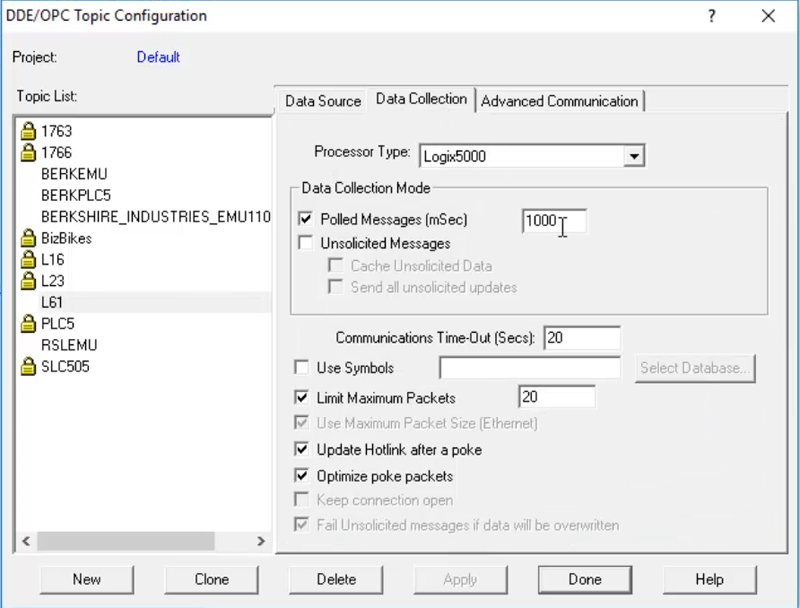

Step 3) Next, select the Data Collection tab and review the default settings:

Step 3) Next, select the Data Collection tab and review the default settings:

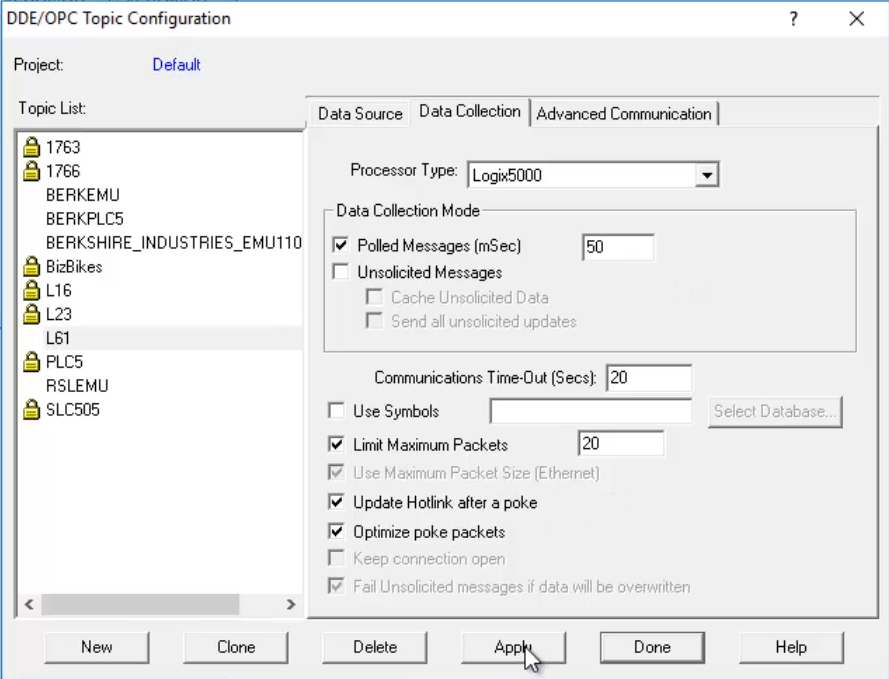

Step 4) When done reviewing the default settings and making any changes, click on the Apply button. Note that in this example I changed the Polled Message rate from 1000ms to 50ms:

Step 4) When done reviewing the default settings and making any changes, click on the Apply button. Note that in this example I changed the Polled Message rate from 1000ms to 50ms:

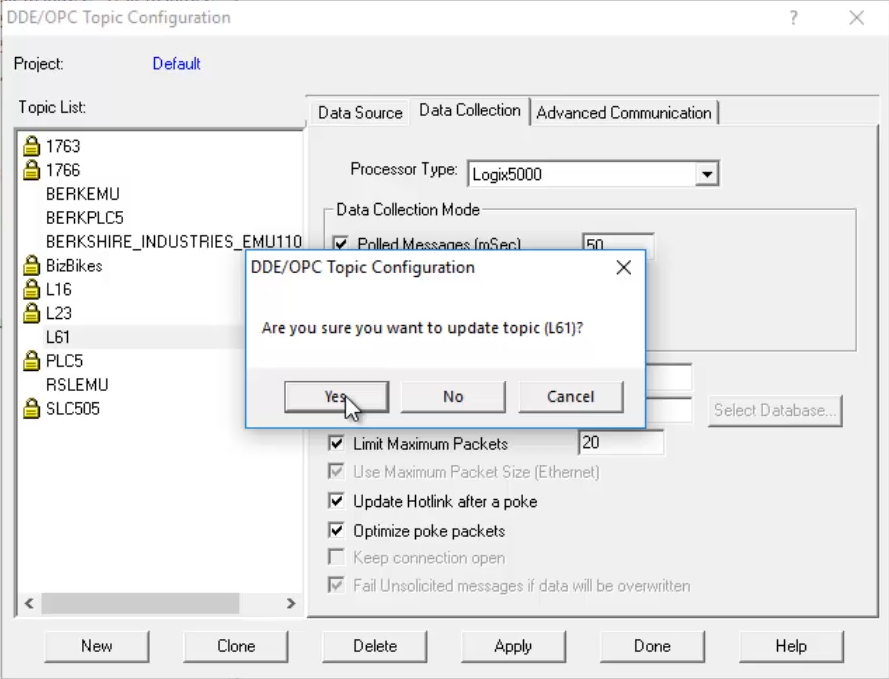

Step 5) When prompted, select Yes to update the topic with your changes:

Step 5) When prompted, select Yes to update the topic with your changes:

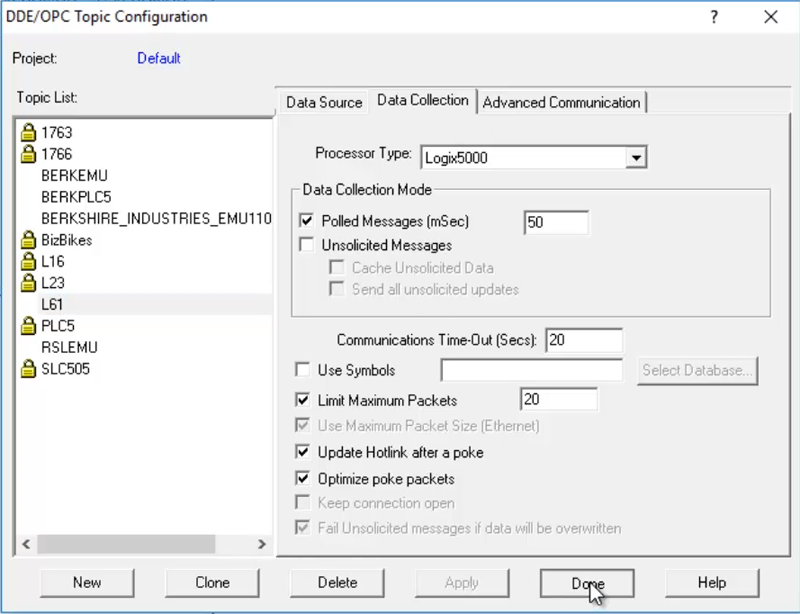

Step 6) Now select Done to close the Topic Configuration window:

Step 6) Now select Done to close the Topic Configuration window:

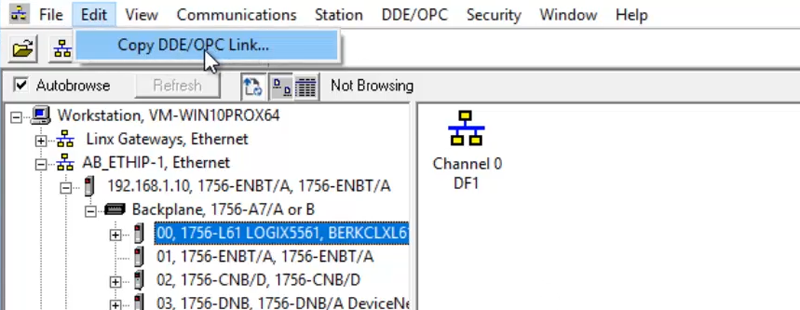

Step 7) Now from the Edit menu (only available in licensed versions of RSLinx Classic as noted previously,) select Copy DDE/OPC Link…

Step 7) Now from the Edit menu (only available in licensed versions of RSLinx Classic as noted previously,) select Copy DDE/OPC Link…

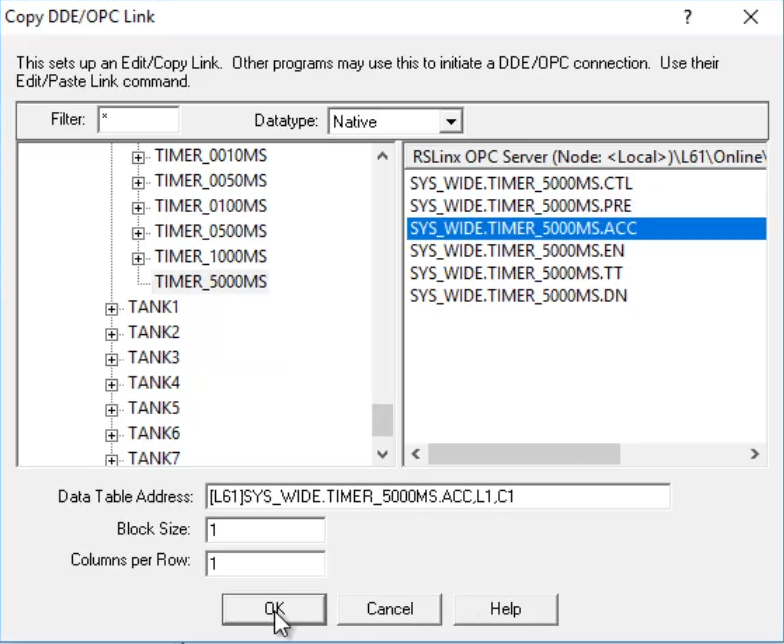

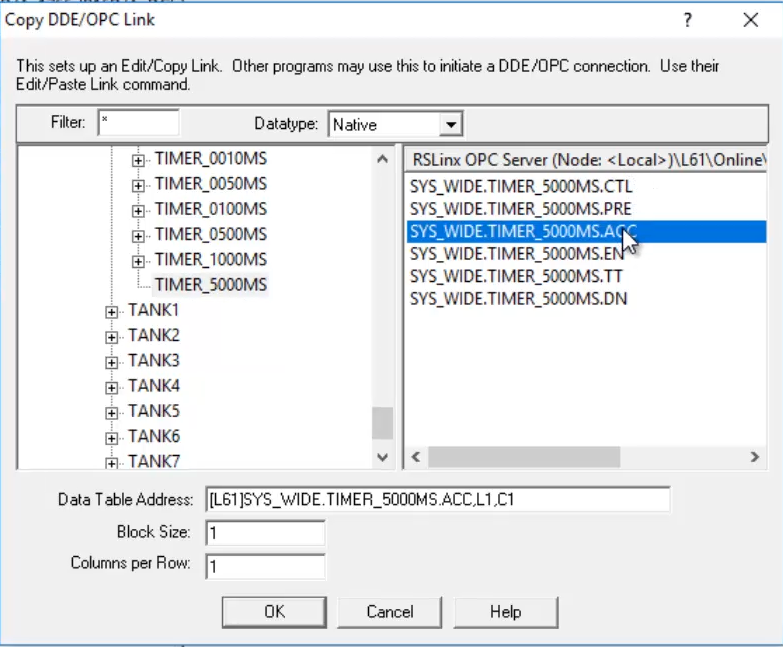

Step 8) Then browse for the address or tag whose value you’d like to display in Microsoft Excel:

Step 8) Then browse for the address or tag whose value you’d like to display in Microsoft Excel:

Step 9) And click on OK when done:

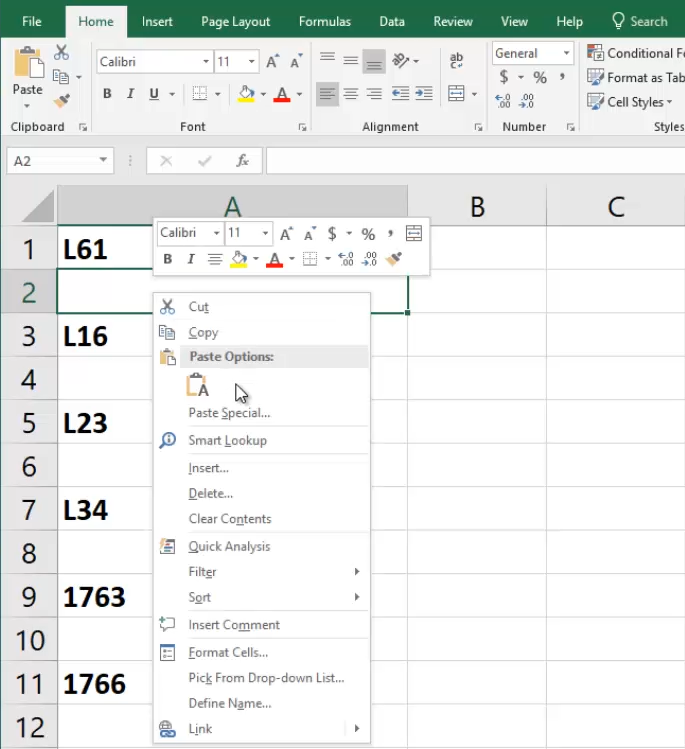

Step 10) Now in Excel, right click on the cell where you’d like the data to appear and select Paste Special:

Step 10) Now in Excel, right click on the cell where you’d like the data to appear and select Paste Special:

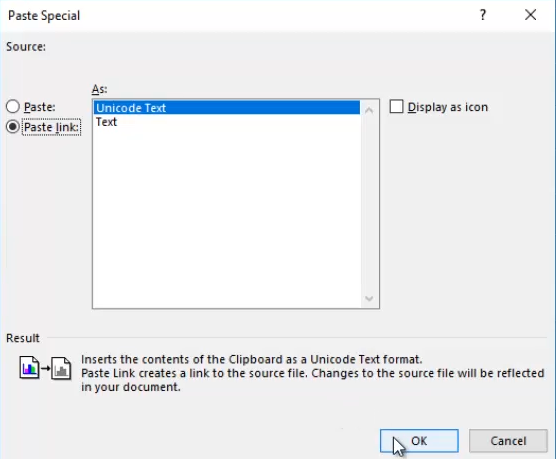

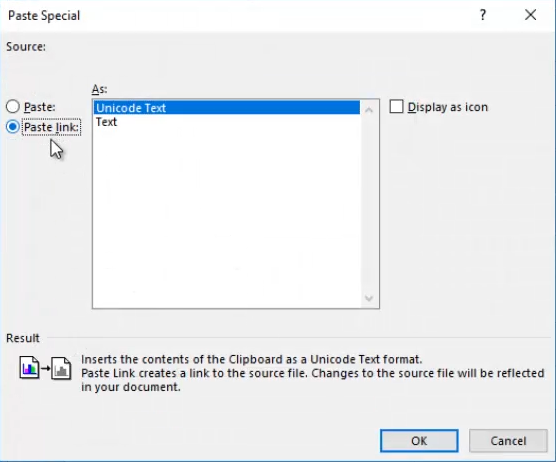

Step 11) Then choose Paste Link:

Step 11) Then choose Paste Link:

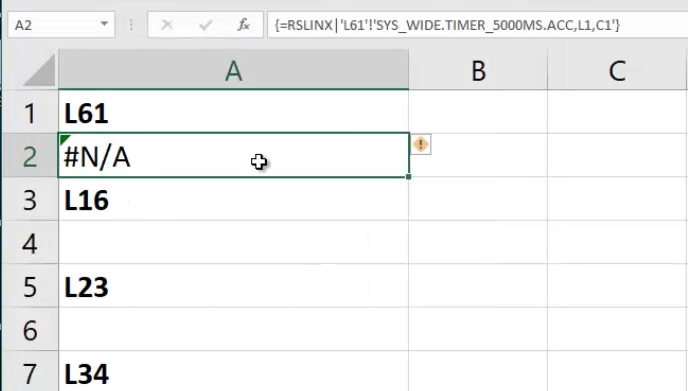

Step 13) At first you may see “#N/A” as the data is being fetched from RSLinx:

Step 13) At first you may see “#N/A” as the data is being fetched from RSLinx:

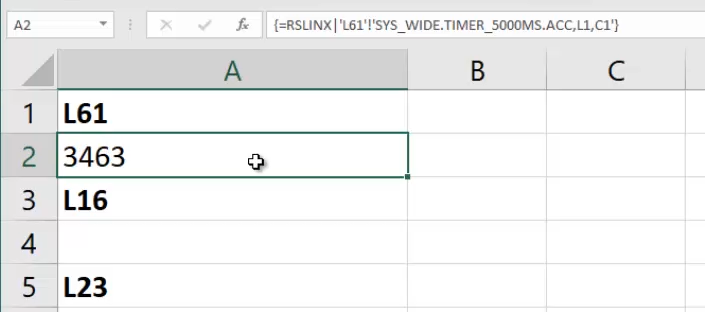

Step 15) However, after a few seconds you should see you Programmable Controller’s live data appear:

Step 15) However, after a few seconds you should see you Programmable Controller’s live data appear:

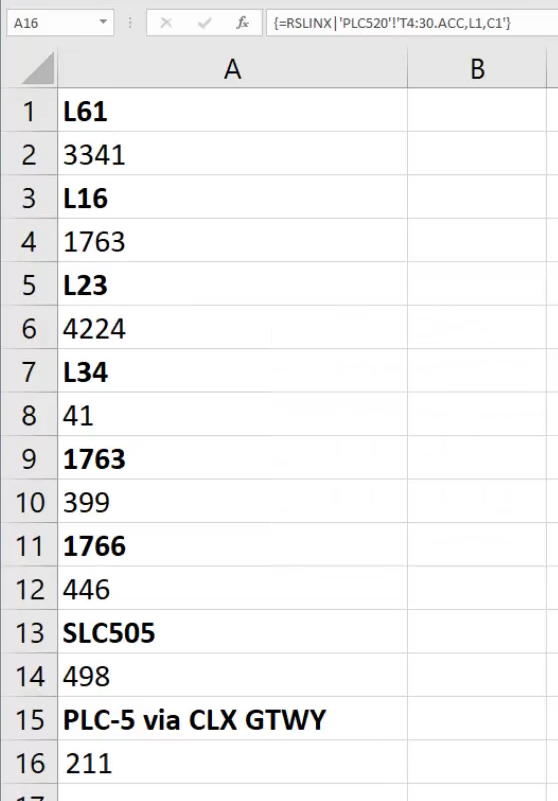

Step 16) This procedure works for ControlLogix, CompactLogix, PLC-5, SLC-500, and MicroLogix as shown below:

Step 16) This procedure works for ControlLogix, CompactLogix, PLC-5, SLC-500, and MicroLogix as shown below:

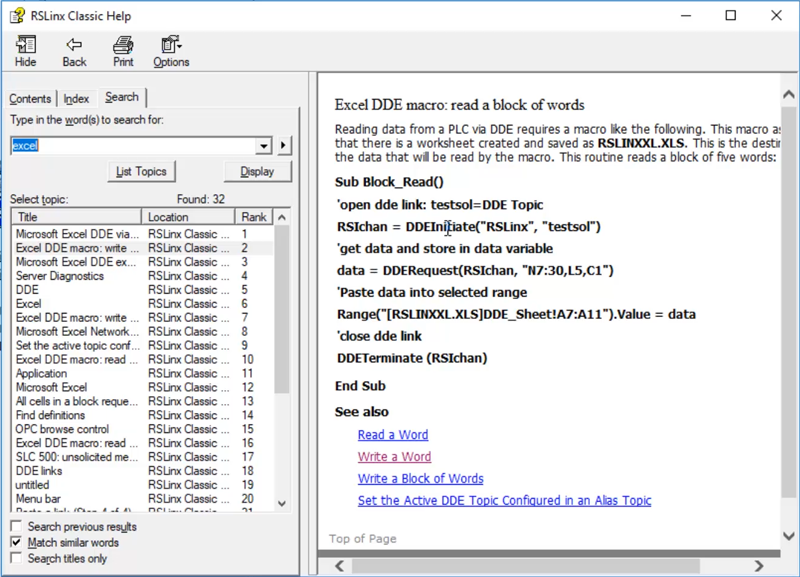

Step 17) If you’d also like to learn how to create a button to upload or download many tag values, search RSLinx Classic’s Help on the word “Excel” for example macros:

Step 17) If you’d also like to learn how to create a button to upload or download many tag values, search RSLinx Classic’s Help on the word “Excel” for example macros:

To watch a video demonstration of the above, check out Episode 41 of The Automation Minute Season 4 below:

If you found this article helpful, please share it with your colleagues on LinkedIn, Facebook, Twitter or Goggle Plus!

And if you know anyone who would benefit from Allen-Bradley PLC, HMI, or SCADA training, please let them know about my affordable courses over at TheAutomation School.

You can also share your own thoughts and opinions on this subject by clicking on the “post a comment or question” link below.

Until next time, Peace ✌️

If you enjoyed this content, please give it a Like, and consider Sharing a link to it as that is the best way for us to grow our audience, which in turn allows us to produce more content 🙂

Shawn M Tierney

Technology Enthusiast & Content Creator

Support our work and gain access to hundreds members only articles and videos by becoming a member at The Automation Blog or on YouTube. You’ll also find all of my affordable PLC, HMI, and SCADA courses at TheAutomationSchool.com.

- FactoryTalk Design Workbench First Look, CCW Comparison - December 19, 2025

- Drew Allen of Grace Technologies on Automation, Safety, and More (P256) - December 17, 2025

- Robotics in Warehouse Automation with Erik Nieves of Plus One Robotics (P255) - December 10, 2025

Discover more from The Automation Blog

Subscribe to get the latest posts sent to your email.

Hello, is it possible to get the name of the topic from another cell?

I have no idea where that spreadsheet from 2018 is, but in the video (3:32 to 3:47) you can see every topic since I just copy and paste the first one and then edit it for each plc.

Shawn

Hello, I was wondering why in the menu to add a topic in the processor type bar I cannot identify which of the multiple options corresponds to a Micro820 and an ML1200 PLC, then I wasn’t sure if these PLCs are compatible for this process.

Best guess, Rockwell didn’t feel they needed to.

By selecting the PLC and creating a Topic you actually don’t have to pick the processor type, as shown in the video.

Also, when the MicroLogix first came out in the 90’s, we got use to selecting SLC-500 when MicroLogix wasn’t an option. (The ML is based on the SLC-500.)

As for the much newer Micro800, check out Rockwell’s knowbase:

https://rockwellautomation.custhelp.com/app/results/kw/opc%20micro800/okcsSearchSession/ZlVWMEZRRUZQWmVDZVI1X2tmSGpTamkxczM1cGhPZFQ3fmFZNXBJRzhtaDNaMUdWRU10dmVXUXQxbkxTNWNaT29zNExCQThGdWdPbFZrYWgyVExkSkxCdVBBZWJiU1Nic2pVSmo1eDh1Mmt3cklIbjdBWkdfMlRRQWRTQnhuRkhSOFdJVE5vc21FNjNFIQ!!/page/1/priorTransactionID/1246320067/transactionID/1246320067

Best wishes,

Shawn

Good morning,

Your question is in broken English, but I believe you’re asking if this procedure works with all A-B PLCs, and it does as long as you have the software described.

Sincerely,

Shawn

Hello. i have a question, is this possible with Micro820 and ML1200? I dont identify el Processor Type for this PLC