PLCs of all shapes and sizes now come with Ethernet communications built-in.

And one of the easiest ways to insure you have network connectivity between your PC and PLC (or other device) is to “Ping” it.

In today’s article I’ll walk you through the simple steps needed to quickly “Ping” your PLC to see if you do indeed have network connectivity to it.

Preface: The “Ping” command is used to test the reach-ability from one device to another on an Ethernet network using Internet Protocol, and is derived from the Naval term.

For more details about the “Ping” command check out Wikipedia here.

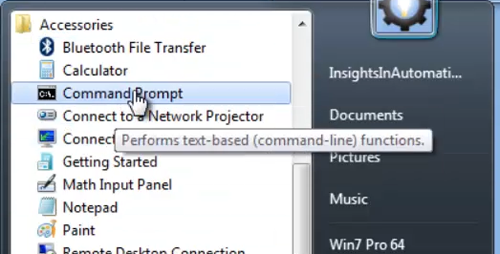

Step 1) The first step is to open a “Command Prompt,” which is found in the Windows Start Menu under Accessories:

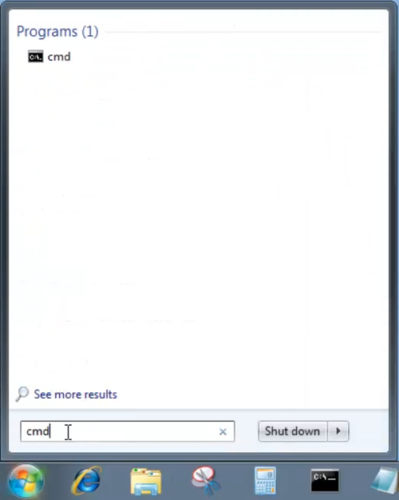

Step 2) You can also open a “Command Prompt” by clicking on “Start,” then entering “cmd” and pressing Enter as shown below:

Step 2) You can also open a “Command Prompt” by clicking on “Start,” then entering “cmd” and pressing Enter as shown below:

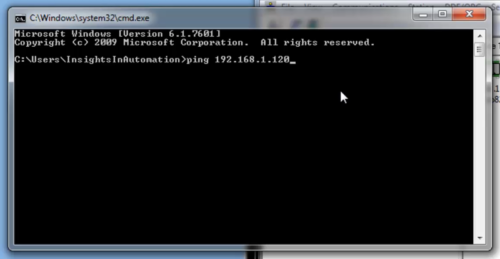

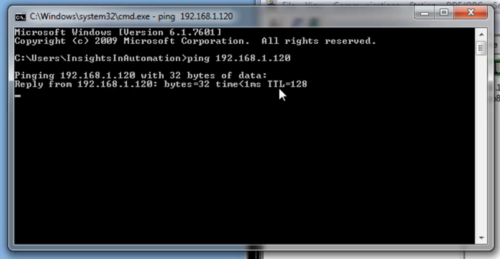

Step 3) Once the command prompt opens, type in the word “ping” followed by a space, and then the Ethernet IP address of your PLC. In the below example I plan on pinging my Micro820 with an IP address of 192.168.1.120:

Step 3) Once the command prompt opens, type in the word “ping” followed by a space, and then the Ethernet IP address of your PLC. In the below example I plan on pinging my Micro820 with an IP address of 192.168.1.120:

Step 4) If you have connectivity from your PC to your PLC, you should see a reply from your ping as shown below:

Step 4) If you have connectivity from your PC to your PLC, you should see a reply from your ping as shown below:

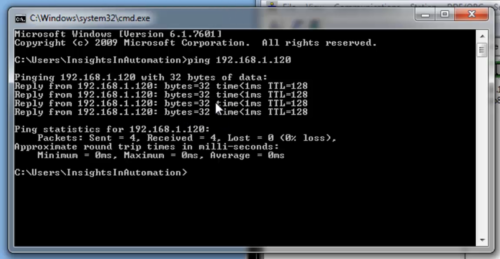

Step 5) After the ping is finished, your screen should look similar to the one below:

Step 5) After the ping is finished, your screen should look similar to the one below:

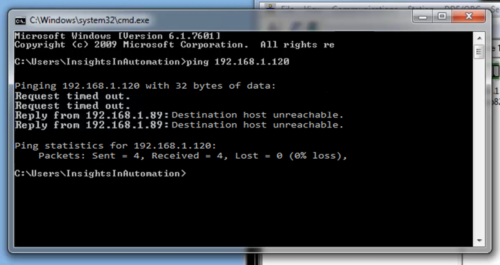

Step 6) If you don’t have connectivity to your PLC, you may see a “Request timed out,” “Destination host unreachable,” or similar message as shown below:

Step 6) If you don’t have connectivity to your PLC, you may see a “Request timed out,” “Destination host unreachable,” or similar message as shown below:

Step 7) If you’re not able to ping your PLC then you very likely won’t be able to program it over Ethernet.

Some reasons you may not be able to connect to and ping your PLC include:

- Loose or bad Ethernet cables, or lack of continuity between the two devices (i.e. the two networks never physically or wirelessly connect to each other)

- Your PC and PLC are assigned to different subnets with no router bridging the two subnets

- Your PC and PLC are assigned to bridged subnets, but your PC or PLC has a missing or incorrect “default gateway” setting

Question) Did you Find this article helpful? If so, please share it with co-workers and colleagues! You can also keep our site online with regular updates with a $1 monthly pledge at TheAutomationBlog.com/join

And to learn everything you need to know to setup and start programming the Micro800 line of programmable controllers, check out my Micro800 course at Nano Basics Course

Below you can watch a video of the above procedure:

I hope you found this article helpful. If you have any questions please feel free to post them at TheAutomationBlog.com/join which I visit each weekday to reply to reader’s questions.

Until next time, Peace ✌️

If you enjoyed this content, please give it a Like, and consider Sharing a link to it as that is the best way for us to grow our audience, which in turn allows us to produce more content 🙂

Shawn M Tierney

Technology Enthusiast & Content Creator

Support our work and gain access to hundreds members only articles and videos by becoming a member at The Automation Blog or on YouTube. You’ll also find all of my affordable PLC, HMI, and SCADA courses at TheAutomationSchool.com.

- A.I. Tech Talk with Emil Soerensen of Kapa.ai (12/04/25) - December 4, 2025

- Innovation Summit Las Vegas 2025 Recap (P254) - December 3, 2025

- New Features of Ignition 8.3 with Travis Cox (S2E37) - December 2, 2025