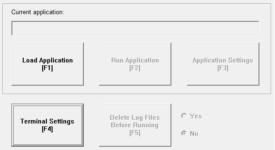

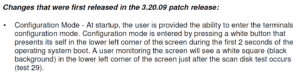

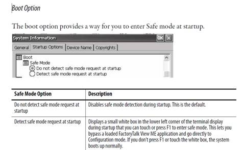

On Monday and Tuesday we discussed how to access the “Configuration Mode” of the PanelView Plus and PanelView Plus 6. One additional way we did not yet cover is using an “autorun.bat” file on a USB Memory Stick (aka USB Thumb Drive, USB Flash Drive.)

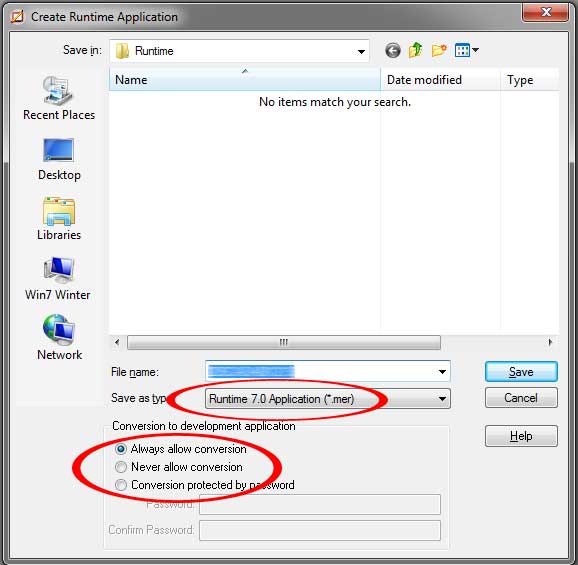

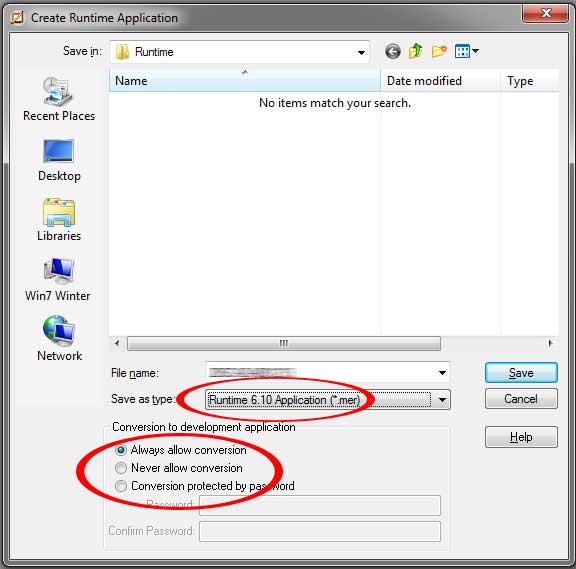

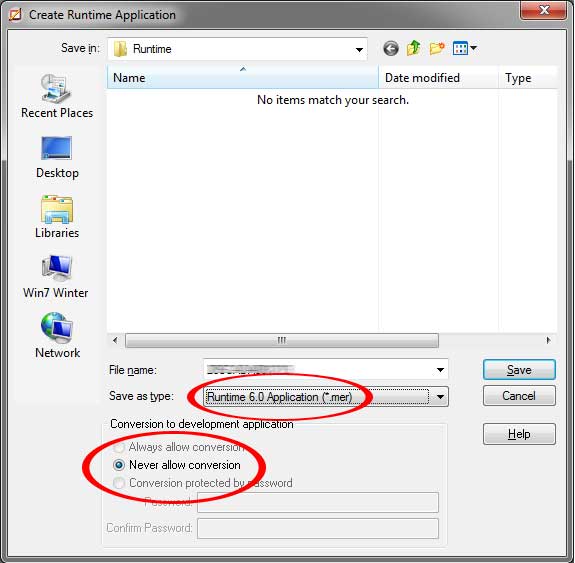

These script are written to automatically move all your FactoryTalk View Machine Edition (ViewME) Runtime Files (.mer) off your terminal so when it’s rebooted it doesn’t find the needed .mer file and therefore returns to the “Configuration Mode.”

The “autorun.bat” file used for this purpose is a simple text based file reminiscent of the old DOS files of the same name.

When you place one of these files in the root folder of your USB Memory Stick, and insert it into your PVPlus, it immediately runs.

And while the commands in the “autorun.bat” file aren’t limited to coping your “.mer” files to and from your USB memory stick, this is what the below samples scripts are designed to do.

The first two scripts are custom ones I created for a client with a PanelView Plus 6 firmware rev 6.0 terminal.

The first two scripts are custom ones I created for a client with a PanelView Plus 6 firmware rev 6.0 terminal.

The first backs up all the .mer files on the terminal to the USB Memory Stick , and then deletes them from the terminal.

The second script copies all the .mer files from the USB Memory Stick back to the Terminal.

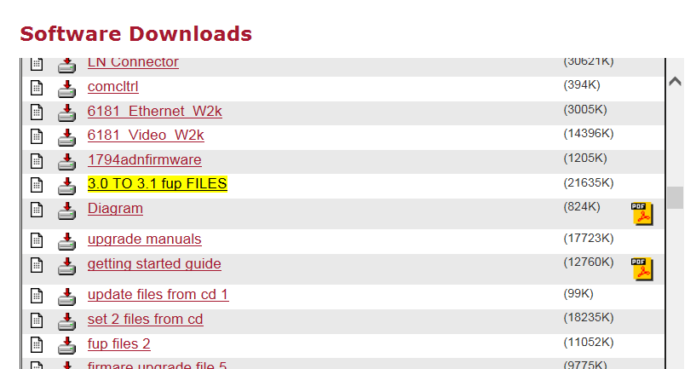

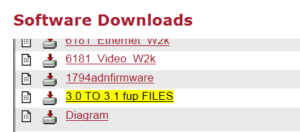

Update 08/11/15: The below scripts are now available as a bundled download here:

Update 08/11/15: I recently received a PVP7s donation (thanks RK!) and can confirm these files also work on it.

Update 08/11/15: I’ve added two new scripts whch have been edited to work on a PanelPlus v5.1, but I also tested them on a PanelView Plus v3.2 and they worked there as well.

PanelView Plus 6 / 7 autorun.bat file script text used to backup .mer files from the terminal to the usb memory stick, and then delete the .mer files from the terminal.

NOTE: This file was tested on a PanelView Plus 6 and PanelView Plus 7 Standard

UPDATE: The below text was updated on 08/11/2015 to correct a typo in the REMarks

echo on

REM BACKUP AND DELETE ALL .MER FOR PVPLUS 6

REM **************************************************************

REM CREDITS: This file was created by Shawn Tierney and may be purchased

REM as part of a bundle for just $0.99 at theautomationblog.com. Thank you in

REM advance for your support!

REM **************************************************************

REM **************************************************************

REM REQUIREMENTS:

REM 1) THIS FILE MUST BE NAMED autorun.bat TO WORK

REM 2) THIS FILE IS FOR PANELVIEW PLUS 6

REM 3) THIS SCRIPT MAY TAKE UP TO 120 SECONDS TO COMPLETE

REM **************************************************************

REM **************************************************************

REM STEP 1 – Make backup MER folder on the PVPlus 6 in case copy fails

CD\application data\rockwell software\rsviewme

MD backup

REM **************************************************************

REM **************************************************************

REM STEP 2 – Copy MER files to the backup directory created above

CD runtime

COPY *.* “\application data\rockwell software\rsviewme\backup”

REM **************************************************************

REM **************************************************************

REM STEP 3 – Copy the MER files to the USB STORAGE DEVICE

COPY *.* “\usb storage”

REM **************************************************************

REM **************************************************************

REM STEP 4- Make correct directory on USB Drive (may already exist)

CD\usb storage

MD “Rockwell Software”

CD Rockwell Software

MD RSViewME

CD RSViewME

MD Runtime

CD Runtime

REM **************************************************************

REM **************************************************************

REM STEP 5 – COPY MER files to correct directory on the USB Drive

CD\Application Data\Rockwell Software\RSViewME\Runtime

COPY *.* “\USB Storage\rockwell software\rsviewme\runtime”

REM **************************************************************

REM **************************************************************

REM STEP 6 – Delete MER files from the PVPlus 6 application directory to

REM force the system to return to Configuration Menu on reboot

DEL *.mer

REM **************************************************************

REM **************************************************************

REM REMINDER – Tell the operators to allow 120 seconds from when they

REM insert the card before they remove it

REM The process is now complete

REM Remove the USB Drive and cycle power to the terminal

REM **************************************************************

REM **************************************************************

REM This file was written & tested by Shawn Tierney, InsightsInAutomation.com

REM and may be purchased as part of a four file bundle for just $0.99

REM at http://www.theautomationblog.com. Thank you in advance for your support!

REM **************************************************************

PanelView Plus 6 / 7 autorun.bat file script text used to copy .mer files from the usb memory stick to the terminal:

NOTE: This file was tested on a PanelView Plus 6 and PanelView Plus 7 Standard

UPDATE: The below text was updated on 08/11/2015 to correct a typo in the REMarks

echo on

REM COPY ALL .MER FILES FROM USB TO PVPLUS 6

REM **************************************************************

REM CREDITS: This file was created by Shawn Tierney and may be purchased

REM as part of a bundle for just $0.99 at theautomationblog.com. Thank you in

REM advance for your support!

REM **************************************************************

REM **************************************************************

REM REQUIREMENTS:

REM 1) THIS FILE MUST BE NAMED autorun.bat TO WORK

REM 2) THIS FILE IS FOR PANELVIEW PLUS 6

REM 3) THIS SCRIPT MAY TAKE UP TO 120 SECONDS TO COMPLETE

REM **************************************************************

REM **************************************************************

REM STEP 1 – Copy all .MER files from the correct directory on the USB Drive

REM to the correct directory on the PanelView Plus 6

CD\Application Data\Rockwell Software\RSViewME\Runtime

COPY “USB Storage\Rockwell Software\RSViewME\Runtime\*.*”

REM **************************************************************

REM **************************************************************

REM REMINDER – Tell the operators to allow 120 seconds from when they

REM insert the card before they remove it

REM The process is now complete

REM Remove the USB Drive and cycle power to the terminal

REM **************************************************************

REM **************************************************************

REM This file was written & tested by Shawn Tierney, InsightsInAutomation.com

REM and may be purchased as part of a four file bundle for just $0.99

REM at http://www.theautomationblog.com. Thank you in advance for your support!

REM **************************************************************

NEW! PanelView Plus 5.1 autorun.bat file script text used to backup .mer files from the terminal to the usb memory stick, and then delete the .mer files from the terminal.

NOTE: This file was tested on a v5.1 and v3.2 PanelView Plus

echo on

REM BACKUP AND DELETE ALL .MER FOR PVPLUS 5.1

REM **************************************************************

REM CREDITS: This file was created by Shawn Tierney and may be purchased

REM as part of a bundle for just $0.99 at theautomationblog.com. Thank you in

REM advance for your support!

REM **************************************************************

REM **************************************************************

REM REQUIREMENTS:

REM 1) THIS FILE MUST BE NAMED autorun.bat TO WORK

REM 2) THIS FILE IS FOR PANELVIEW PLUS FIRMWARE 3.0 TO 5.1

REM 3) THIS SCRIPT MAY TAKE UP TO 120 SECONDS TO COMPLETE

REM **************************************************************

REM **************************************************************

REM STEP 1 – Make backup MER folder on the PVPlus in case copy fails

CD\storage card\rockwell software\rsviewme

MD backup

REM **************************************************************

REM **************************************************************

REM STEP 2 – Copy MER files to the backup directory created above

CD runtime

COPY *.* “\storage card\rockwell software\rsviewme\backup”

REM **************************************************************

REM **************************************************************

REM STEP 3 – Copy the MER files to the USB STORAGE DEVICE

COPY *.* “\usb storage”

REM **************************************************************

REM **************************************************************

REM STEP 4- Make correct directory on USB Drive (may already exist)

CD\usb storage

MD “Rockwell Software”

CD Rockwell Software

MD RSViewME

CD RSViewME

MD Runtime

CD Runtime

REM **************************************************************

REM **************************************************************

REM STEP 5 – COPY MER files to correct directory on the USB Drive

CD\storage card\rockwell software\rsviewme\runtime

COPY *.* “\usb storage\rockwell software\rsviewme\runtime”

REM **************************************************************

REM **************************************************************

REM STEP 6 – Delete MER files from the PVPlus application directory to

REM force the system to return to Configuration Menu on reboot

DEL *.mer

REM **************************************************************

REM **************************************************************

REM REMINDER – Tell the operators to allow 120 seconds from when they

REM insert the card before they remove it

REM The process is now complete

REM Remove the USB Drive and cycle power to the terminal

REM **************************************************************

REM **************************************************************

REM This file was written & tested by Shawn Tierney, InsightsInAutomation.com

REM and may be purchased as part of a four file bundle for just $0.99

REM at http://www.theautomationblog.com. Thank you in advance for your support!

REM **************************************************************

New! PanelView Plus 5.1 autorun.bat file script text used to copy .mer files from the usb memory stick to the terminal:

NOTE: This file was tested on a v5.1 and v3.2 PanelView Plus

echo on

REM COPY ALL .MER FILES FROM USB TO PVPLUS 5.1

REM **************************************************************

REM CREDITS: This file was created by Shawn Tierney and may be purchased

REM as part of a bundle for just $0.99 at theautomationblog.com. Thank you in

REM advance for your support!

REM **************************************************************

REM **************************************************************

REM REQUIREMENTS:

REM 1) THIS FILE MUST BE NAMED autorun.bat TO WORK

REM 2) THIS FILE IS FOR PANELVIEW PLUS FIRMWARE 3.0 TO 5.1

REM 3) THIS SCRIPT MAY TAKE UP TO 120 SECONDS TO COMPLETE

REM **************************************************************

REM **************************************************************

REM STEP 1 – Copy all .MER files from the correct directory on the USB Drive

REM to the correct directory on the PanelView Plus

CD\storage card\rockwell software\rsviewme\runtime

COPY “\usb storage\rockwell software\rsviewme\runtime\*.*”

REM **************************************************************

REM **************************************************************

REM REMINDER – Tell the operators to allow 120 seconds from when they

REM insert the card before they remove it

REM The process is now complete

REM Remove the USB Drive and cycle power to the terminal

REM **************************************************************

REM **************************************************************

REM This file was written & tested by Shawn Tierney, InsightsInAutomation.com

REM and may be purchased as part of a four file bundle for just $0.99

REM at http://www.theautomationblog.com. Thank you in advance for your support!

REM **************************************************************

IMPORTANT: Please note, copying the above text from inside internet explorer may replace the standard “quotes” with angled “quotes,” which will in turn cause the copy and make directory functions to fail when executed on the PanelView Plus.

Update: The above scripts are now available as a bundled download here:

Hopefully the above autorun scripts will come in handy if you ever lock yourself out of your PVPlus, or if you just want an easy way to backup all your .mer runtime files on your terminal.

If you have any stories about being locked out of your PVPlus, or have a similar script to share, please click on the “post a comment or question” link below to share your comments with the rest of us.

Until next time, Peace ✌️

If you enjoyed this content, please give it a Like, and consider Sharing a link to it as that is the best way for us to grow our audience, which in turn allows us to produce more content 🙂

Shawn M Tierney

Technology Enthusiast & Content Creator

Support our work and gain access to hundreds members only articles and videos by becoming a member at The Automation Blog or on YouTube. You’ll also find all of my affordable PLC, HMI, and SCADA courses at TheAutomationSchool.com.

Shawn Tierney is a lifelong Technology Enthusiast who began programing in the early 80's on the Apple II and VIC-20 personal computers. After earning a degree in Electronics, he worked as a Certified Controls and Information Automation Specialist for 25 years before launching The Automation Blog and School in 2013.

Latest posts by Shawn Tierney

(see all)(no views)

Option 1: Log to CompactFlash or SD Memory

Option 1: Log to CompactFlash or SD Memory Option 2: Log internally to array, retrieve with MS Excel and RSLinx Classic

Option 2: Log internally to array, retrieve with MS Excel and RSLinx Classic Option 3: PanelView Plus CE or 6 (or ViewME Station) DataStore ActiveX

Option 3: PanelView Plus CE or 6 (or ViewME Station) DataStore ActiveX Option 4: XLReporter from SyTech

Option 4: XLReporter from SyTech  Option 5: FactoryTalk View Site Edition

Option 5: FactoryTalk View Site Edition  Option 6: FactoryTalk Historian SE

Option 6: FactoryTalk Historian SE

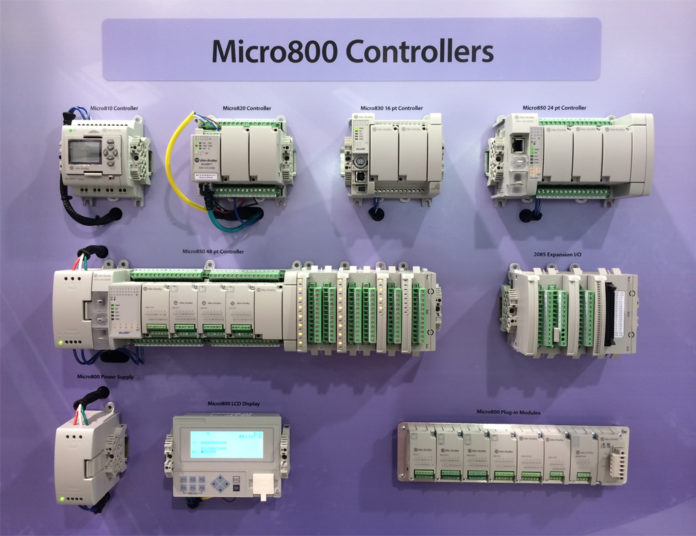

In my opinion, the Micro800 family of Micro PLC’s will give you the most value for your money.

In my opinion, the Micro800 family of Micro PLC’s will give you the most value for your money.